views

X

Research source

Masking Your Vehicle

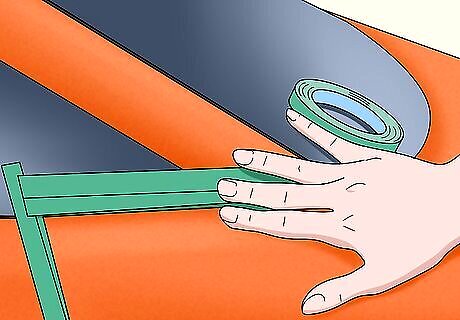

Cover anything that isn’t painted with masking tape to protect it. Grab a roll of masking tape and walk around your vehicle. Use the tape to cover up any plastic edges, the trim around your windows, any emblems on your vehicle, and the edges of your headlights. Mask off any portion you don’t want to damage with the abrasive polisher you’re going to use.Warning: You’re going to use a polishing tool to apply an abrasive compound. If you don’t mask off the areas you want to protect, you may end up damaging or scratching them.

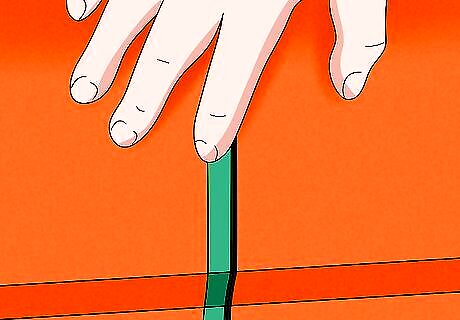

Add tape to any portions of your panels that aren’t flat or smooth. If you have any ridges, racing stripes, or images on the vehicle’s panels, tape them off. Use horizontal strips of tape to cover any edges that sit on an angle to protect them. It’s exceptionally difficult to remove orange peel from these edges without damaging them, so you’re better off just taping them off. The polishing tool is flat. This means that any angular or textured portions of the vehicle won’t fit the shape of the polishing tool. You’re more likely to dent the panel than remove the orange peel in these areas.

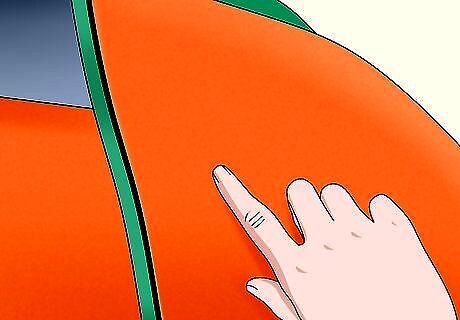

Pick a panel to start with and tape off the edges on the adjacent panels. Choose any panel to start with. Then, tape off the seams on the panels surrounding your starting panel. For example, if you’re starting on the hood, add pieces of tape to the panels surrounding each wheel next to the hood. Just to clarify, you do not tape the edges of the panel you’re working on. Otherwise, you wouldn’t be able to remove the orange peel near the seams. You only need to tape off the adjacent panels because the rotary polisher may bend them if you don’t sand them out from the center of the panel. This will keep the polishing tool from brushing against any sensitive edges at the wrong angle. If you don’t do this, you may scratch or bend an adjacent seam on your door. As you work, you’ll peel off these pieces of tape and apply new pieces of tape to the seams on the next set of panels. It doesn’t matter where you start. You’re going to remove the peel from each panel one at a time so you can start wherever you’d like.

Setting up Your Rotary Polisher

Pick up a fast cut compound designed for vehicles to buff the bumps out. The best way to remove orange peel without sanding is to use fast cutting compound. Cutting compound is an abrasive paste that will erode an extremely thin layer of paint and wear away the orange peel in the process. Pick up some fast cutting compound at a local automotive or construction supply store. Cutting compound is commonly used to buff vehicles and remove scratches. It will definitely remove the orange peel, though. You’ll need roughly 32 fluid ounces (950 mL) of compound to cover a mid-sized 4-door vehicle.

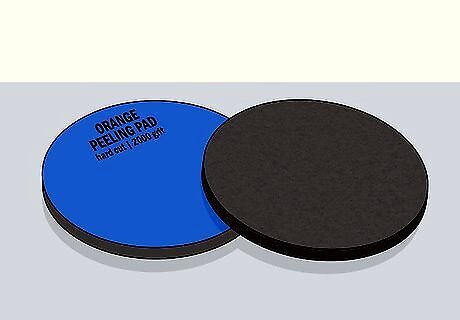

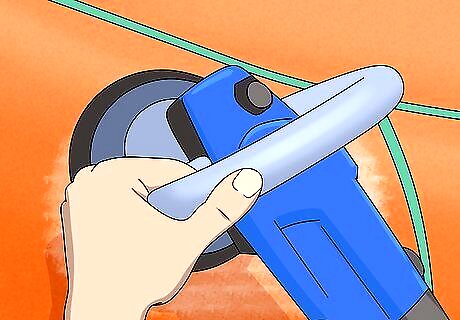

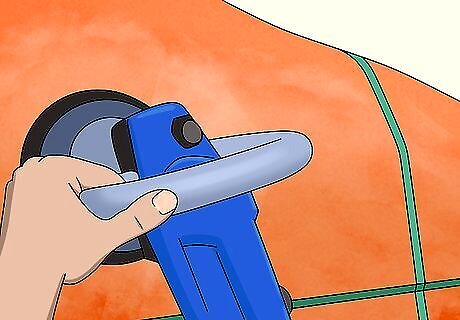

Attach an orange peel removal pad to a rotary polisher. Buy or rent a rotary polisher, which is basically a big orbital sander designed for buffing cars. Get an orange peel removal pad or a denim pad, and slide the edges of the pad over the disc on the front of the rotary polisher.Warning: Do not use a wool or foam pad. The orange peel basically looks like a series of waves when you look closely at it. Wool and foam will fill the ridges of these waves and may make the orange peel worse. Denim and orange peel removal pads are flat and won’t fill the gaps between the waves, which means they’ll smooth the wavy ridges down evenly. For the specialty pads, they’re literally marketed as “orange peel removal” pads. They’re typically some kind of combination of velvet, denim, and foam. Denim is a great choice and many people prefer it over the orange peel removal pads. You likely won’t notice much of a difference between the two if you don’t do this for a living, though. You cannot do this without a rotary polisher. You can buy a rotary polisher for $150-400, or rent one from your local construction supply store for roughly $15-20 a day.

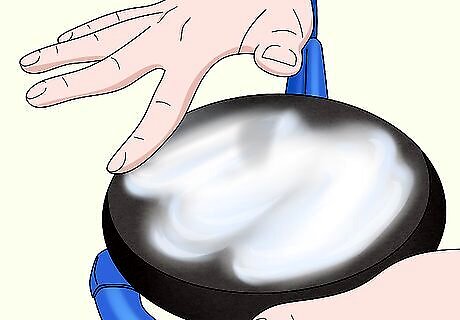

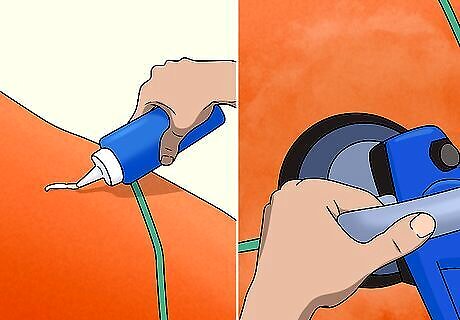

Spread a 12–16 in (30–41 cm) bead of compound around the pad to prime it. Put on a pair of nitrile gloves and turn your rotary polisher over. Pour fast cutting compound out of the nozzle and spread it on your denim or orange peel removal pad in a zigzag pattern. Then, use your gloved finger to spread the compound out so every portion of the pad is covered in a thin layer of the paste. You don’t need to do this if the pad you’re using has been used to remove orange peel at least 2-3 times before this.

Removing the Orange Peel

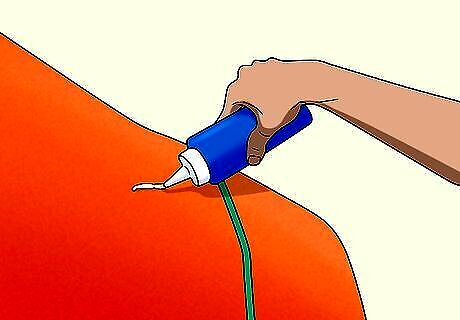

Apply a 6–12 in (15–30 cm) bead of compound to the first panel. Take the bottle of cutting compound and spread a thick line of paste over any portion of the first panel. It doesn’t necessarily matter where you start. You’re going to work in 2–3 ft (0.61–0.91 m) sections, so just pick an any area to start. Some people like to start in the middle and work their way to the edges, while others prefer starting on a corner and working in. It’s really up to you.

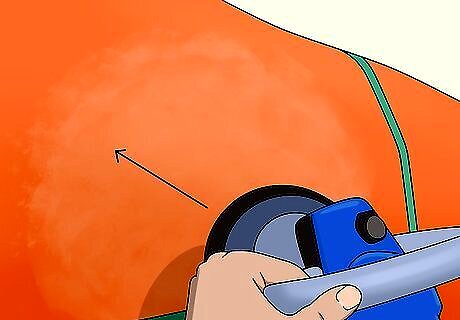

Spread the compound around the panel in a 2–3 ft (0.61–0.91 m) section. With your polisher off, hold the pad flat against the panel where you applied the compound. Move the pad back and forth to spread the bead of cutting compound out in a square- or rectangle-shaped section. Once you’ve covered a small portion of the panel with your compound, you’re ready to start buffing. This ensures that every portion of the panel in the area you’re working gets a little compound. If you don’t spread it out, you may not end up with an even coat of paint.

Set the rotary polisher to 600 rpm and work in a circular motion. There is a dial on the handle of the rotary polisher. If the rpm isn’t listed on the dial, set it to “1” or “low.” Otherwise, set it to 600 rpm. Pull the trigger to spin the polishing pad and hold it gently against the panel. Move the pad in a smooth circular motion while applying light pressure to the vehicle to begin removing the orange peel.Tip: You really don’t need to press very hard. Pretend like you’re petting a cat or brushing someone’s hair back. It’s a very light pressure.

Cover the area where you spread the polish out 3-5 times. Keep moving the polishing pad around in a smooth circular motion. If the area is round, keep turning the polisher so that the pad is resting parallel to the area that you’re working on. Cover each portion of the area where you originally spread the compound out 3-5 times until the paint looks a little paler and less reflective than the surrounding area. If you cover an area more than 7-8 times, you may produce too much heat from the friction and begin wearing away the paint. Don’t overdo it. You can always repeat this process again after the panel cools from the first round of buffing.

Keep polishing until the paint is paler and less reflective than the rest of the vehicle. Somewhere between the third and fifth cycle with the polishing pad, the orange peel will be gone. Pay attention to the color of the paint and the way it reflects light to determine when you’ve worn it away. Typically, when the orange peel is gone, the paint will look a little less glossy, reflect less light, and the area will be a little paler than the rest of your vehicle. It should be pretty obvious when the orange peel is gone. Depending on how thick the orange peel was, you may physically be able to see the difference in the texture.

Repeat this process on the rest of your panels to remove the peel. When you’re done with the first area, add a bead of compound to the section next to it, spread it out, and buff it with the pad 3-5 times. When you finish the first panel, tape off the adjacent seams on the next panel and repeat the process all over again. This process may take 30-60 minutes. Don’t forget to tape the new seams whenever you go to a new panel. You are allowed to tape off a seam on panels you just buffed out in case you’re curious. It won’t damage the recently-buffed paint. Run your gloved hand over the paint when you’re done. If it doesn’t feel smooth and even, reapply compound to any areas that aren’t smooth and buff them out.

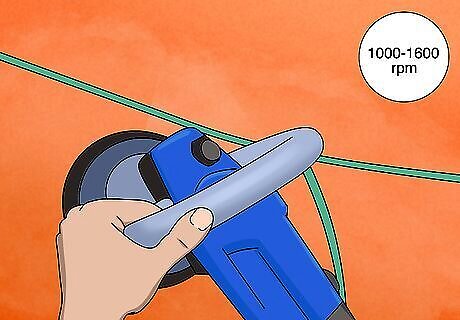

Polish everything at 1000-1600 rpm when you’re done buffing the paint. Once you’ve buffed the entire vehicle, repeat the entire process. This time, cut the amount of cutting compound you use in half, apply no pressure, and use the highest rpm available on your polisher. This will even out any mistakes, remove any scratches, and make your car look practically new. Cover each area 1-2 times to finish polishing your vehicle. Continue re-taping the seams as you work. Let the vehicle air dry when you’re done.

Comments

0 comment