views

India is set to welcome its first, homegrown ultraviolet ray contactless sanitisers, in a bid to aid the fight against Covid-19. Built by Mumbai-based Nevon Solutions, the product is available in two varieties — portable and stationary, and is already being supplied to hospitals and public departments in a bid to step up the battle against Covid-19. Alongside being a crucial product, the UV-C sanitiser suits PM Modi’s new ‘vocal for local’ initiative. It also costs about Rs 4,000 per device, which is at least half of UV-C steriliser wands, and significantly lesser than the industrial ultraviolet sanitisers made by global companies.

Speaking to News18, Neeraj Sawant, the founder and managing director of Nevon Solutions, stated that about 35 units of the UV-C sanitisation devices have already been seeded to organisations, and more units are on the way.

The products

Based off a model of a UV sanitisation device being used in China, Sawant states that Nevon’s products are the only production-ready UV-C sanitisation devices that are available in India right now, and even the prototype device showed by the Defence Research and Development Organisation (DRDO) are not yet ready for mainstream development. Sawant started working on the products from March 2020, but stated that his company already had prior experience in working with UV products, which helped the process.

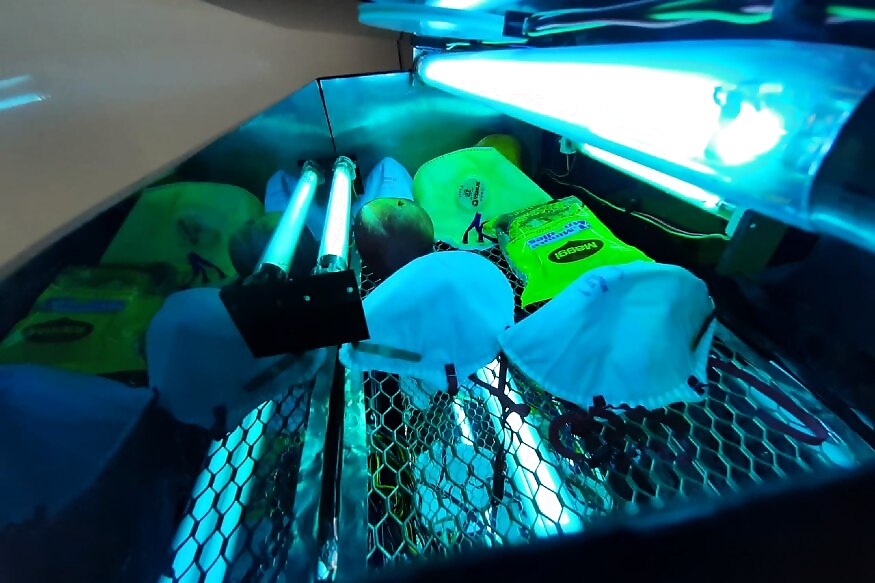

The products in question are of two types. The first is a handheld, portable UV-C sanitiser that has a unidirectional throw, and can be used for sanitising public spaces such as shared seating in hospital waiting areas, etc. The second, which is a stationary device, can be used for sanitising N95 masks at hospitals, and therefore be reused going forward. To tune the devices in order to offer the right magnitude of UV-C intensity, Sawant says that he downloaded the SARS coronavirus data from publicly available WHO and CDC resources, and used it to simulate the amount of ultraviolet rays that would be enough to kill virus and bacteria on a surface.

To address any concerns around accidental injuries and burns, Sawant said that he has been offering personal usage warnings to all parties to whom he has already seeded the products to, and aims to include sufficient usage directives in the future products that he would provide. He also states, “We have done numerous engineering validation tests on the device to ensure that there are no risks of accidental skin burns, and that the sanitiser does not decrease the capability of the N95 masks.” Right now, Sawant says that due to the lockdown, numerous supply and production chains remain closed in the country, which is why the pace of production of the products still remains slow.

As proof of validation of the homegrown UV-C sanitisers, Sawant sent News18 undertaking certificates and recommendation letters from the Naval Dockyard, and Pune University’s Science & Technology Park — an undertaking of the government of India’s department of science and technology.

Adoption so far

According to Sawant, his UV-C sanitiser products are already being used in INHS Ashwini in Colaba, Mumbai — a naval hospital. News18 could independently verify this with an INHS Ashwini official. In the Mumbai Police departments, takers for Sawant’s sanitisers include the offices of Dr Rashmi Karandikar, deputy commissioner of police (Mumbai port zone), Nishith Mishra, additional commissioner of police, and the Wadala Police Station.

Sawant further claims that he already has a bunch of pending orders, which he will confirm as per production speed. Some of his future clients for the sanitiser devices include Dr Vipul Nayar, ophthalmologist at Vision Eye Hospital, Delhi, and even extend to overseas orders, such as Dr Defkalion Alexakis, principal dentist at You Smile Dental Care in Lincoln, UK.

Production and cost

According to Sawant, the production of the sanitisers have so far been handled in two parts — one, at his own workshop for Nevon Solutions, and two, via outsourced manufacturers. However, there have been roadblocks that he is facing at the moment. “We are producing about 25 sanitiser units per week right now, but the demand is higher. However, due to the lockdown, it has been difficult to get outsourced partners since many facilities are still shut. I already have permission letters from state government to go about the process, but not enough partners are available to take on the project.”

Once the norms are eased, Sawant says that the aim is to increase production to about 150 units per day, which can be a significant uptick. When asked about whether regular consumers can also buy the product, Sawant said, “Eventually, yes. But right now, our aim is to sufficiently supply public service and healthcare departments, which will take some time. Once production increases, we will certainly look to sell it to everyone.”

Both the handheld and the static UV-C sanitiser products cost about Rs 4,000, said Sawant.

Comments

0 comment