views

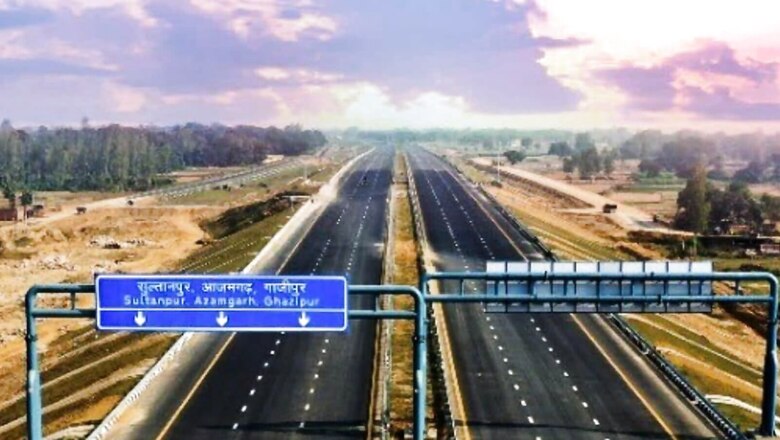

In a big move, the Narendra Modi government has decided to apply the concept of ‘value engineering’ to all ongoing and upcoming national highway projects in the country that could reduce the cost of the projects as well as ensure better quality and their quicker completion.

News18 has accessed a detailed order issued by the Centre on Tuesday to all state chief secretaries and chiefs of the NHAI, NHIDCL and Border Roads Organisation (BRO). The new orders cover all highway, tunnel and bridge projects being undertaken in the country.

‘Value Engineering’ involves use of alternative designs, material or technology for construction of projects that are cost-effective, improve durability and safety, increase the speed of construction without compromising the quality, promote environmental sustainability and increase resilience to climate change, the order says.

“The Concessionaire or Contractors shall be entitled to retain all the savings accrued to them on account of value engineering practices adopted by them. The content of this circular shall be applicable for all the ongoing/upcoming projects henceforth and until any further orders,” the order says.

Concessionaires have been apprehensive that adverse views would be taken about any alternative technologies so they avoid any deviations from the specifications so far and feared long-term risks upon them of adopting such innovative practices. The order mentions that it will now “dispel such apprehensions and mind-set”.

These practices will now be implemented right from project inception, project preparation, project bidding stage and project implementation. The order cites a World Bank report on the India’s road construction industry which says that savings realised by undertaking value engineering exercises can be 10-15% of the cost of the originally designed project. India has about 1.41 lakh km length of National Highways and progress of 37 km per day was achieved for development works during 2021-22.

What Changes Now?

The order says that value engineering can be applied at any point in a project, even in construction, but “the earlier it is applied the higher is the return on the time and effort invested and also the acceptance”.

The order says that ‘value engineering’ practices have been added for the design, construction and maintenance of the national highways.

The order added that ‘value engineering’ shall be assigned as one of the tasks in the Terms of Reference (ToR) for Feasibility Study and Detailed Engineering Projects and in the inception report itself, there shall be a Chapter regarding Value Engineering, in which the Constant shall include the potential & project-specific value engineering aspects identified by the respective domain experts based on site reconnaissance surveys.

“In the Feasibility Report, the consultant shall examine the identified value engineering aspects and recommend the cost-effective strategies. During the design stage, the design shall be done for the approved value engineering criteria and considering the same the schedules and project costs shall be prepared. During the project appraisal, Value Engineering Practices will be examined and finally adopted. Further during implementation, the concessionaire/contractors shall be allowed to propose vague-engineering which will be reviewed,” the order says.

What Are Value Engineering Techniques?

The order has listed out a series of value engineering techniques that can be adopted for projects. “Component of a highway project generally comprises of 70% of material costs, 20% of machineries costs and 10% of manpower costs. Hence, to have a value-engineered optimum highway emphasis shall be on material selection and design,” the order says.

It cites use of select soil treated with hydrated lime, cement, fly ash or pond ash and use of soiI stabilizer. It also mentions exploitation of maximum soil strength using technology, reduction in the designed pavement composition and less burning of bitumen.

The other value engineering moves would be ensuring minimum rate of bitumen from the government refinery and private producers, minimum rate of steel from SAIL/TISCO and private manufacturers, rate analysis of concrete be taken considering 20% fly ash, use of fibre reinforced polymers and allowing glass/carbon/aramid fibre reinforced polymer that can bring reduction of 5-10% in the cost.

The order also cites use of locally available road building material, industrial waste and municipal solid waste landfill for road construction. Use of bonded concrete pavement, short-panelled concrete pavement and pre-tensioned pre-cast concrete pavement has also been proposed.

Use of expansive black cotton soil available in Maharashtra, Madhya Pradesh, Andhra Pradesh, Chhattisgarh, Gujarat and Karnataka; reuse of excavated soil; reuse of reclaimed bituminous layer material that is usually dumped along national highway and use of fibre reinforced micro-surfacing as an eco-friendly treatment has been proposed too.

Other techniques proposed are use of high-damping rubber bearing, use of pre-cast structures, use of soil stabilised earthen shoulder, use of construction and demolition waste and 100% recycling of reclaimed bituminous layer. “The quantum of the aged highways asset is increasing, which warrant rehabilitation to extend its life further. It is prudent to reclaim the bituminous layer material and reuse as much as permitted,” the order says.

The order also asks for promoting use of new sustainable materials for bridges such as stainless steel and weathering steel, use of modular, prefabricated, adaptable and re-usable structures for temporary, emergency and permanent bridges in remote areas and use of fibre reinforced or high-strength concrete for the tunnel works.

“With such value engineering practices, there may be a reduction of initial project cost to the tune of 20-30%. Besides this, there is time saving, less consumption of road building materials and less emission without compromising performance durability of the National Highways Asset,” the order says.

Read all the Latest News India and Breaking News here

Comments

0 comment