views

Making Cardboard Substitute

Gather your materials. You'll need five sheets of paper and some glue. A glue stick or some craft glue will work the best. The dimensions of your paper will affect the size of your cardboard, so use smaller paper if you want a smaller piece of cardboard. Using more sheets of paper will result in thicker cardboard. If using liquid glue, consider spreading out some newspaper to catch any glue that drips off of your cardboard.

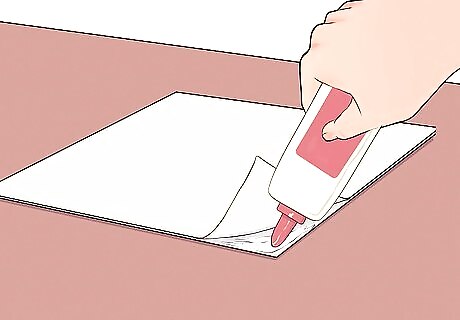

Glue two sheets of paper together. Spread your glue on one side of a sheet of paper, then align a second sheet of paper and stick them together. The corners and edges should align as closely as possible. This will form the foundation for your cardboard.

Firmly press the sheets together. Run the heel of your hand across the foundation, both from the bottom of the page to the top and from side to side. Make sure all sides and corners are glued together. If any edges or corners are loose, pull them apart as little as possible and add more glue. Reattach the sheets and press together again.

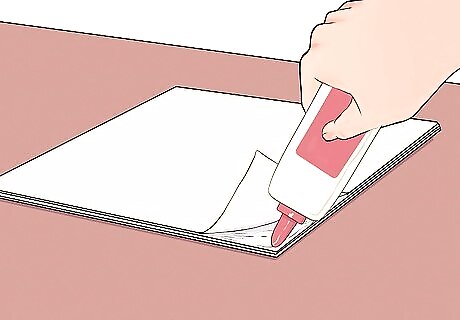

Glue additional sheets of paper on to your foundation one at a time. Spread glue on the top page of your foundation, then align and attach another sheet of paper. Make sure to line up the corners and edges before sticking the pages together. Firmly press down on the foundation after each sheet of paper is added to make sure all of the paper is staying glued together. Continue to add sheets onto the foundation until your cardboard is the desired thickness. Adding more sheets of paper will increase the thickness of your cardboard.

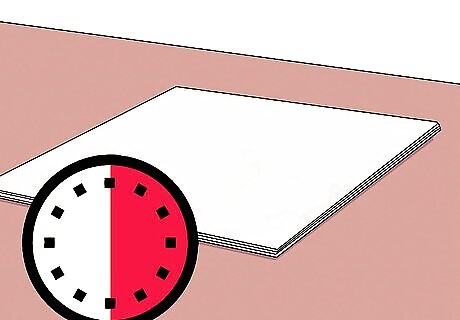

Let the glue dry for 30 minutes. Put your cardboard under a fan or in a warm location to speed up the drying process. Be patient! If the glue doesn't dry completely your cardboard may fall apart.

Making Corrugated Cardboard

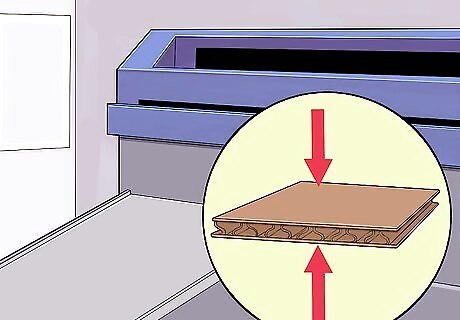

The industrial process of making cardboard boxes uses a machine called a corrugator. Cardboard is simply a sheet of ridged paper sandwiched in between two sheets of flat paper. The corrugator organizes and assembles the three different sheets to make corrugated cardboard. The ridged paper increases the stability and durability of the cardboard while using a relatively small amount of paper.

The ridged sheet is made by running paper through the corrugator. The machine heats the flat paper to 350 degrees Fahrenheit and pushes it through ridged rollers. The result is a sheet of paper with a repeating U-shaped design that will be used as the core of the cardboard.

A flat sheet of paper is glued to each side of the ridged sheet. The corrugator applies a starch-based glue to one side of the ridged sheet, which is then pressed onto a sheet of flat paper. The same process is used to apply another flat sheet to the untouched side of the ridged sheet, creating the familiar corrugated sheet of cardboard.

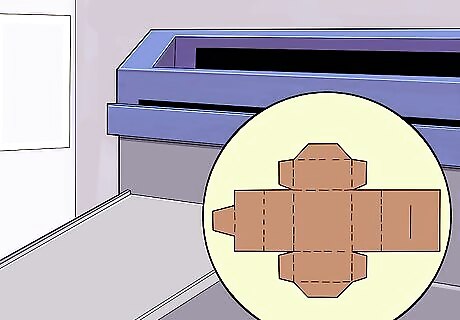

The large sheet of corrugated cardboard is then cut based on the desired size and shape. Further cuts and perforations are made to allow for folding into various shaped boxes and containers.

Comments

0 comment