views

- Use a drill bit designed for whatever material you’re installing the rivet in to drill a pilot hole for the nut; the bit should be slightly smaller than the diameter of the rivet nut.

- Carefully drive the pilot hole into the surface where you’re installing the rivet using the lowest drill speed setting necessary.

- Slide the rivet nut into the mandrel of a rivet nut tool and pull the mandrel all the way back in the housing.

- Hold the rivet nut over the pilot hole and close the handles on your rivet nut tool to force the nut into place.

- If the rivet nut won’t slide into the opening, expand your pilot hole by using a slightly bigger drill bit.

Drilling a Hole

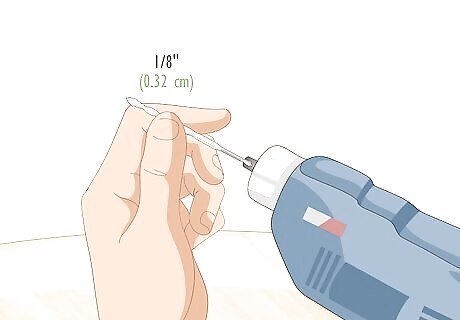

Fit a ⁄8 inch (0.32 cm) drill bit into a power drill. In order to drill a clean hole through the metal, you need to start with a small drill bit to create a tiny hole. Rotate the chuck, or end of the drill, to open the jaws that clamp onto the bit. Insert a small drill bit into the end of your power drill, hold the chuck again, and squeeze the trigger to close the jaws and hold the bit in place. Make sure the drill bit is held securely by tugging at it. Use a ⁄8 inch (0.32 cm) drill bit or smaller to start.

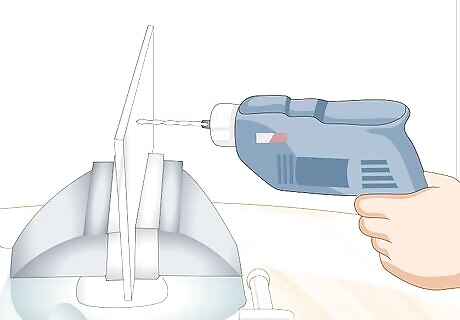

Place the bit against the metal and start drilling slowly. Bringing the drill to full speed before you set it against the metal can cause it to shoot off in another direction and potentially scratch the surface. Place the drill bit against the surface and bring the drill up to speed slowly. Thin metal sheets or softer metals such as aluminum will be easier to drill through. Bring the drill to full speed so it can push through the metal.

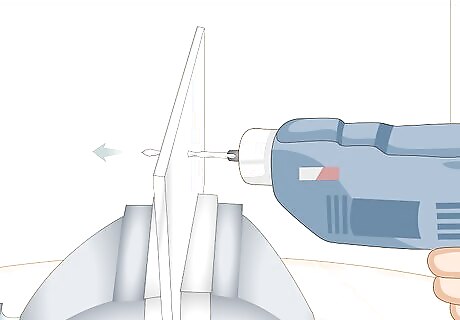

Push the drill bit through the metal. While the drill bit is spinning, apply constant pressure by pushing against the drill with your hands. Eventually, the drill bit will penetrate the surface of the metal. Push it through the metal to create an even hole. Don’t use jerky movements or attempt to shove the drill bit through the metal or it could move out of place and scratch the surface.Tip: Slide the drill bit in and out of the hole a few times to give a smooth edge to the hole.

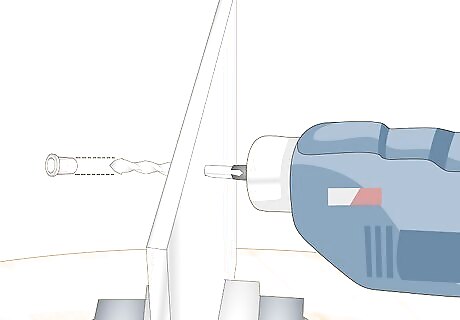

Increase the size of the drill bit to widen the hole until the rivet nut fits. Swap out the drill bit for one with a larger diameter and place the end of it into the hole you made with the smaller bit. Bring the drill up to speed slowly and apply pressure to it. Drive the drill bit through the hole to create a wider opening. Try sliding the rivet nut into the hole whenever you change bits to see if it fits. Whenever it slides into place, stop increasing the size of the hole. Try to fit the rivet nut into the hole before you widen it further.

Fitting the Rivet Nut onto the Mandrel

Connect a mandrel and nosepiece that fits your rivet nut to the tool. On a rivet nut tool, the mandrel is a rod that holds the rivet nut in place when you’re securing it to the metal and the nosepiece holds the rivet nut on the tool when you’re installing it. Slide it into the tool and screw on the nosepiece that secures it and allows you to thread your rivet nut onto the tool. Most rivet nut tools have several mandrels of different sizes, so choose the one that fits the rivet nut you plan to install.Tip: If you can’t locate where you need to insert the mandrel on your tool, check the owner’s manual, or look up the make and model of your tool online.

Open the handle of the rivet nut tool. The handle of the tool needs to be loaded up so you can drive the rivet nut into the hole and install it. Use both hands to pull the handles of the tool apart so it’s fully open and is ready to receive the rivet nut. If you try to install the rivet nut with the handle closed, the tool will not work.

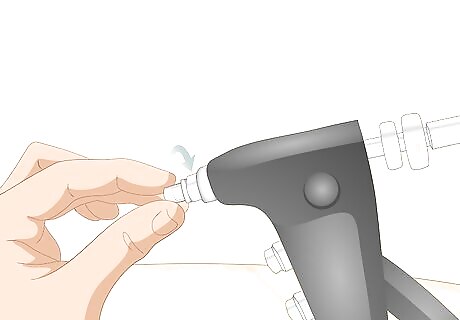

Screw the rivet nut onto the nosepiece of the mandrel. At the end of the mandrel is a threaded nosepiece. Attach the rivet nut by screwing it onto the end of the mandrel until it’s flush with the end of the tool. You will see the very end of the mandrel inside of the rivet nut.

Pull the end of the mandrel back and wind the adjuster. With the rivet nut flush against the end of the tool, pull on the back end of the mandrel. It will slide back a little bit and allow you to turn the adjuster knob to tighten it. Turn the knob until it’s flush against the back edge of the tool. Tighten the knob well so the mandrel is held securely.

Securing the Rivet Nut

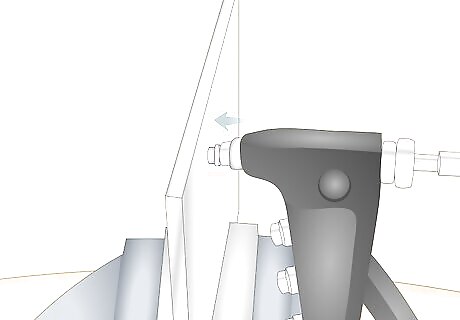

Insert the rivet nut into the hole. Hold the handles of the tool and slide the rivet nut into the hole. Press the edges of the nut so they’re even and flush against the edge of the metal you’re installing it into. Avoid installing the rivet nut at an uneven angle or it won’t be as secure.

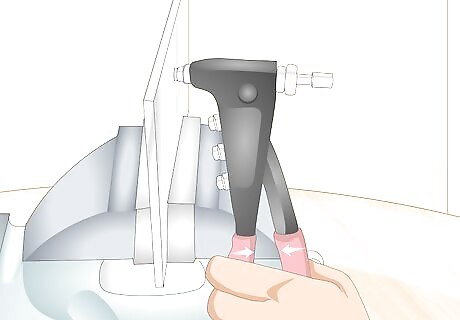

Squeeze the handles of the tool together. Use both of your hands to press the 2 handles of the rivet nut tool together. The tool will force the rivet nut to expand inside of the hole, which will connect it to the metal. You won’t hear a “click” or a “pop” when the tool is finished install the rivet nut. Bring the handles together as far as you can.Warning: Avoid forcing or jamming the handles of the tool together or you could damage the threading of the rivet nut and make it unusable.

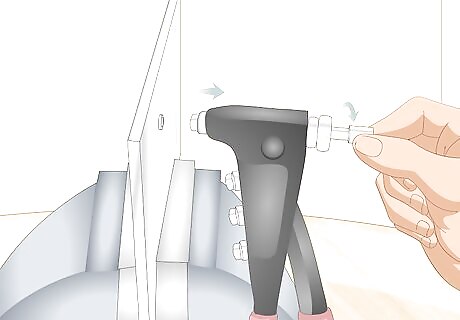

Unscrew the mandrel to complete the installation. Unscrew the adjuster knob at the end of the tool and slide the tool off of the mandrel. Then, turn the mandrel to unscrew it from the rivet nut attached to the metal. You can now use the rivet nut to install screws to the metal. Use your fingers to try to wiggle the rivet nut to make sure it’s secure.

Comments

0 comment