views

- Fix a tiny hole with spackling paste and a small putty knife before painting over the dried spackle.

- Apply mesh tape to golfball-sized holes and spread joint compound over the patch, letting it dry for 24 hours before painting the patch.

- Fix large sheetrock holes by cutting away the damaged area and replacing it with new sheetrock, sealing it with joint compound and sheetrock tape.

- Remove the loose plaster from lath walls, screwing down loose lath before applying two coats of plaster patching compound and letting it dry.

Fixing a Very Small Hole in a Wall

Purchase spackling paste and a small putty knife if repairing a very small hole. Very small holes are usually caused by nails or screws and can be repaired easily and quickly with spackle. There are a variety of spackling pastes for sale. It's usually a good idea to get a lightweight spackling paste that uses the new primer technology, so that a crack does not develop at the seam between the wall and the patch. Small cracks between molding and trim can be filled with spackling paste but it is probably easier to use paintable caulk, which is available at any home improvement store. Simply run a bead of caulk along for crack and smooth with a wet finger.

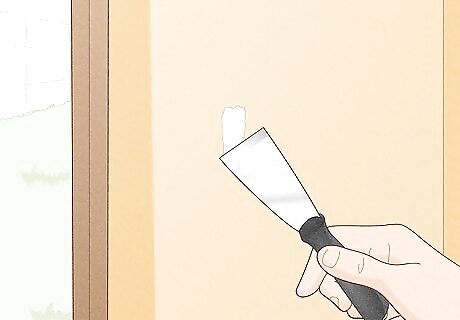

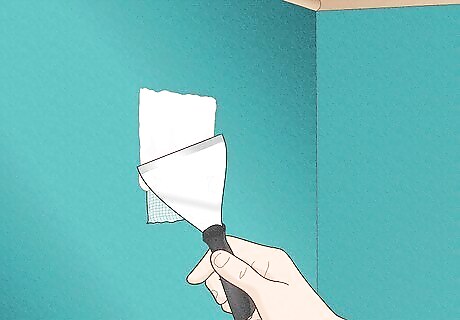

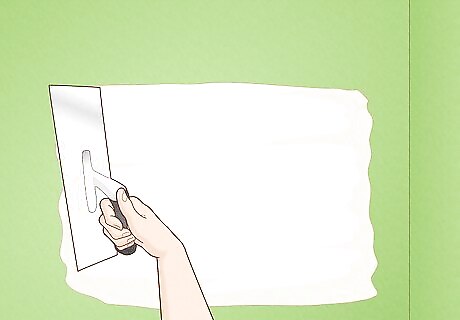

Spread a small amount of spackling paste over the hole with your putty knife. Do not put a lot of spackling paste on your knife. While it depends on the size of the hole, you will usually only need a small bit approximately the size of a pea.

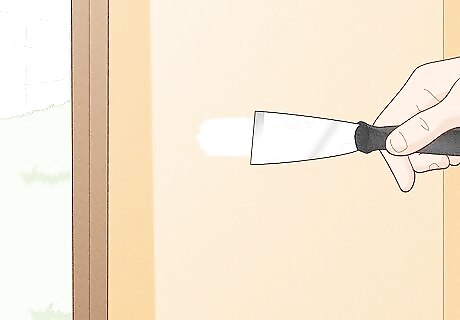

Smooth the spackling paste out with your putty knife. The goal is to make the transition between the wall and the patch as seamless as possible. Using a damp cloth, wipe off any excess spackling paste that may have gotten on the wall around the hole. If you mess up the smoothness of the patch, feel free to start over with a bit more spackling paste on your putty knife.

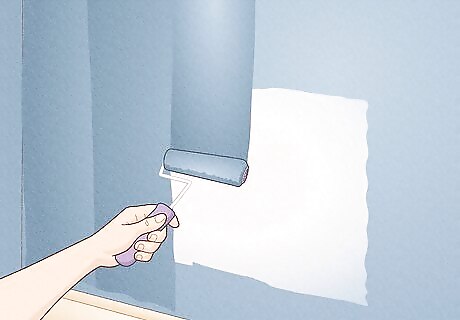

Allow the spackling paste to dry and then paint the patch, if necessary. Sometimes a hole is so small and your wall color is light enough that retouching the paint is not necessary.

Fixing a Golfball Sized Hole in a Wall

Gather and purchase all the supplies and tools you will need. Get all of your tools and supplies together before you get started. To patch a hole the size of a golf ball, you will need: Fiberglass mesh tape or sheetrock tape A small amount of joint compound A 4” drywall knife 220 grit sandpaper

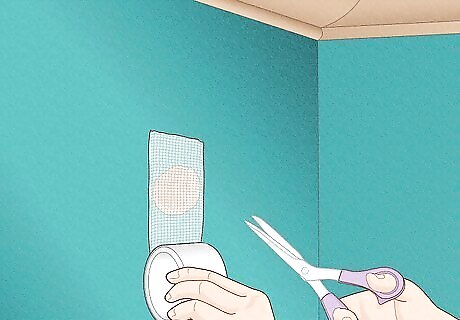

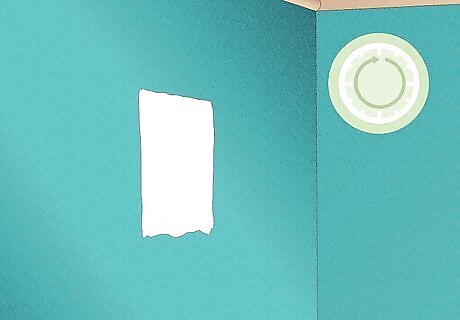

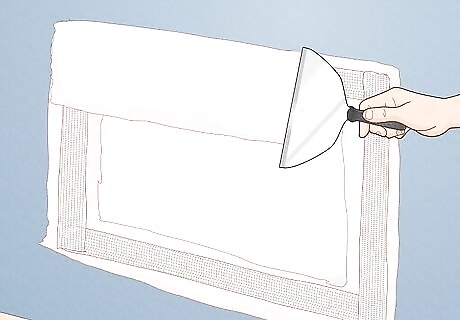

Apply fiberglass mesh tape or sheetrock tape over the hole. A piece of sheetrock tape soaked in water is cheapest but a patch sticks, flattens better, and is thinner. Holes the size of a golf ball and smaller can also be backed with some tight fitting plug or lid or can simply be taped over. Any rise caused by the patch can be feathered out with joint compound.

Apply joint compound, also called 'mud', over the patch. Use your drywall knife to get it on the wall and smooth it out. Mud is usually held in a 'California Cake Pan' or small rectangular box about 4 x 12". If you are planning on doing a lot of sheet rock work in the future, it might be a good idea to purchase one. If you only plan on doing this one repair, don't waste the money. Some people also prefer using something called a “hawk.” This works well for stucco.

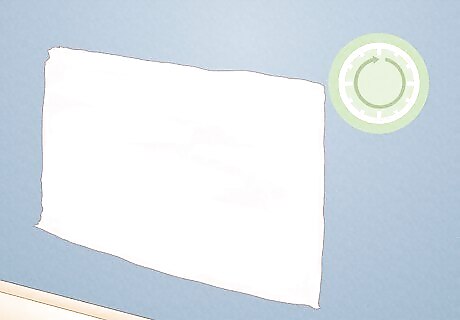

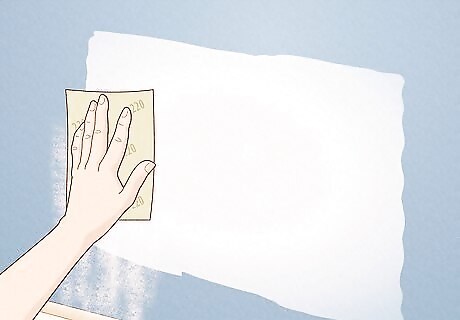

Allow your patch to dry, which should take at least 24 hours. Keep applying thin layers until they are feathered out and smooth. Once dry, sand your patch as needed with a 220 grit sandpaper. Keep going until you cannot feel any seams between the patch and the existing wall.

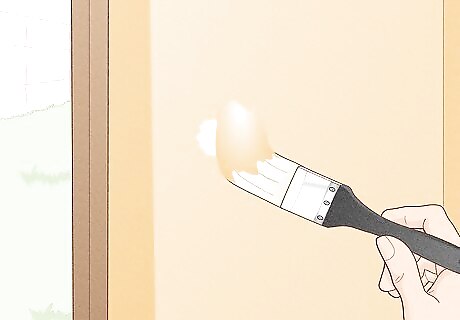

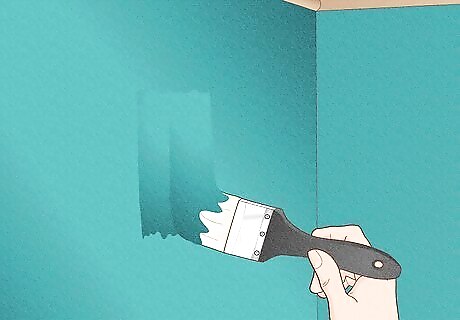

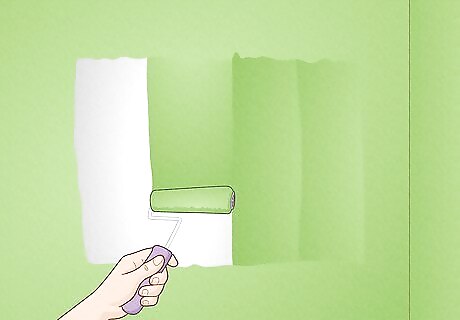

Paint the patch to match the rest of the wall. Make sure that you have gotten all of the dust off the area that you created when you sanded. Make sure to prime the area first.

Fixing a Large Hole in a Sheetrock Wall

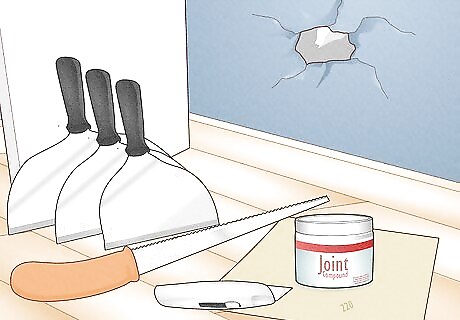

Gather and purchase any materials you will need. All of the items you will need should be available at any big home improvement store. For a large hole in a sheetrock wall you will need: A piece of sheetrock. Since you may only need a piece of sheetrock that is a few feet square, see if you or a friend has a piece of it lying around, instead of buying a whole sheet. However, most home improvement stores also sell smaller pieces of sheetrock. Make sure that the sheetrock is the same thickness as the sheetrock on the wall you are repairing. Residential walls are typically 1/2" and ceilings are 5/8". Commercial walls and ceilings are always 5/8". Joint tape Joint compound A set of drywall knives in sizes 6", 8" and 12" Sandpaper A sheetrock saw A razor-knife

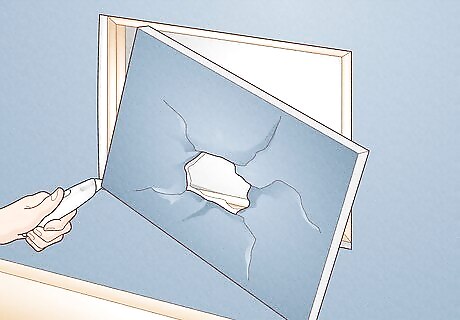

Cut out the damaged area of sheetrock. To fix a large hole you will need to cut out a piece of the wall all the way to the center of each stud on either side of the hole. Make sure your cuts are parallel to each other. This will allow you to attach a new piece of sheetrock to the studs. Use a razor-knife to cut down the center of the stud. Then, make horizontal cuts with a drywall saw. This will allow you to attach your new piece of sheetrock to the stud.

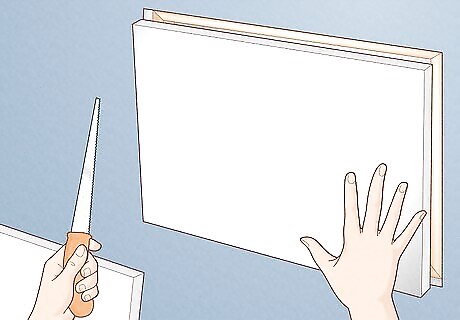

Cut a new piece of sheetrock the size of the hole you made. This may take some finessing if the hole is an odd shape. Screw it to the stud on both sides using one screw every six inches or so. Use your razor knife to make small adjustments to the size of your patch. The sheetrock saw is better for rough in cuts.

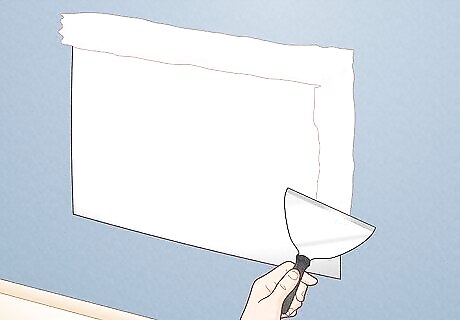

Apply a thin layer of joint compound into the seam around the patch. This layer of joint compound is simply making a bed on which the fiberglass mesh tape can be applied.

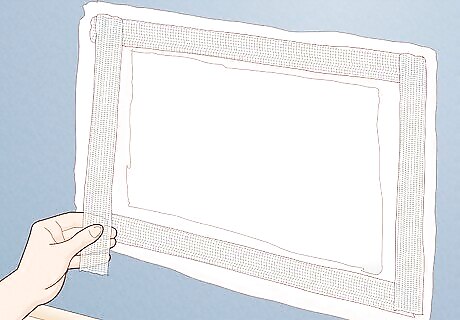

Apply the sheetrock tape to all sides around the patch. The tape is pressed into the mud completely flat and the excess mud is scraped off with your trowel. Sheetrock tape comes dry but needed to be dunked in water before it is stuck to the wall. Tape can be of any length and should be overlapped about an inch when put together.

Apply mud, or joint compound, in a straight line over the length of tape used. This can be allowed to dry or a second coat can be applied immediately, so as to cover the tape.

Allow to dry overnight. Once completely dry, apply a third coat of mud if you think there will be areas where the mud is not smooth.

Sand with 220 drywall mesh sandpaper. Sand until the surface of the joints is smooth.

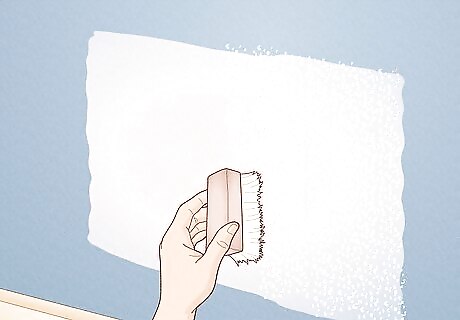

Try to reproduce any wall texture, if necessary. When patching, one of the main problems is matching texture. Texture can be hard to match since it is usually machine blown. To texture patches, a stiff stipple brush will often do the trick, by sticking brush in plaster and stippling on finished and dry patch. If necessary, after it sets up a little, trowel over it to flatten high spots. Keep in mind that home improvement stores usually carry three different types of aerosol texture: knockdown, orange peel, and popcorn

Prime and then paint the entire wall. Large areas like sheet rocked whole walls and rooms should be primed really well for toughness and seal. Follow the primer with painting the entire wall.

Fixing a Large Hole in a Lath and Plaster Wall

Gather and purchase your materials. Get your supplies together before you begin. To fix a lath and plaster wall you will need: A plaster patching compound A large joint or finishing trowel Sandpaper Coarse grade screws for wood and fine grade screws for metal. Choose screws that are 1-1/4" to 1-5/8".

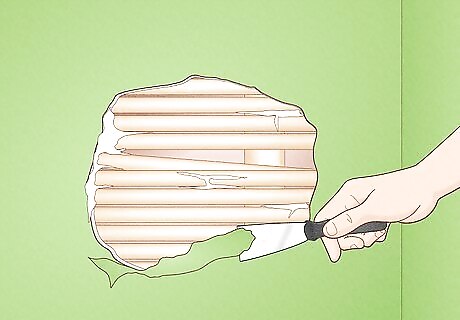

Remove loose plaster. You will need to remove all of the damaged area while making sure to not expand the damage. Gently remove any cracked or loose plaster, moving out from the center damaged area until all the plaster you encounter is secure.

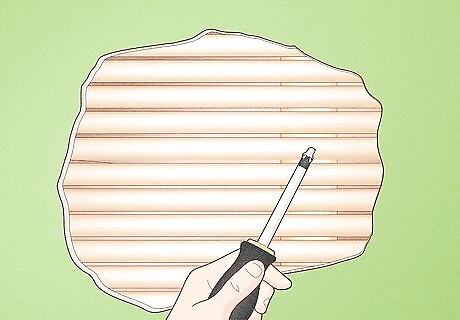

Screw down any loose lath to the studs underneath. Use sheetrock screws but if the lath is cracked add wide thin washers to the screws when screwing down the lath. If some of your lath is damaged so much that it will not hold up plaster, you will need to replace it.

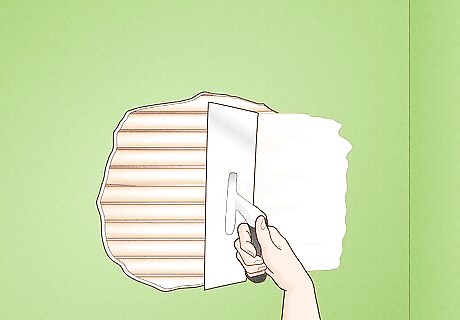

Apply your plaster patching compound to the hole. This is the rough in coat, so the surface of the patch should be a bit below the surface of the wall and does not need to be sooth. Allow this layer to dry for a bit, until the surface is slightly firm but not hard. The consistency of this layer of plater patch should be like peanut butter.

Apply a second coat with your trowel. This coat should stick to the first one but the goal here is to give the surface a smooth surface that is level with the wall. This layer of patching compound should be just slightly thinner than the one underneath. This will allow you to more easily smooth out the surface with you trowel.

Allow the patch to dry completely. Sand the surface with 220 grit sandpaper if you did not get the surface smooth enough with your trowel. Getting a completely smooth surface with a trowel will take a lot of practice, so don't be discouraged if you need to do a bit of sanding on your first try.

Reproduce any wall texture if your walls are textured. Matching texture can be very difficult since it is usually machine blown. However, you can also get aerosol cans of texture in home improvement stores. To texture patches stick a stiff stipple brush in plaster and apply to finished and dry patch. If necessary, after it sets up a little, trowel over it to flatten high spots.

Prime and paint your patch. Always use a good primer or a paint plus primer on plaster walls, as it will protect the wall and saves on cost of finish paint.

Comments

0 comment