views

Using a Plunge Router

Pick a routing bit shaped like the groove that you want to cut. A router is a handheld machine that has a rotating bit to easily carve lines and grooves. There are many different bits that you can attach to your router so you can carve differently-shaped grooves. If you want a groove shaped like the letter V for decorative purposes, then use a V-groove bit. If you want the groove to have flat sides and a flat bottom to use for joining wood, use a straight bit on the router instead. If you don’t have the bit you need, you can buy sets of router bits from your local hardware store or online.

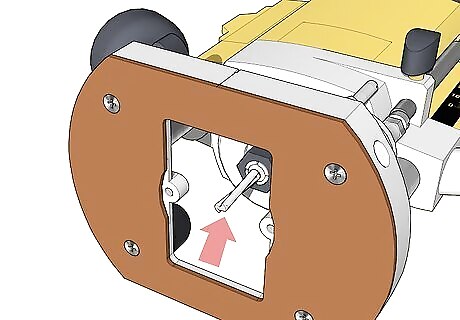

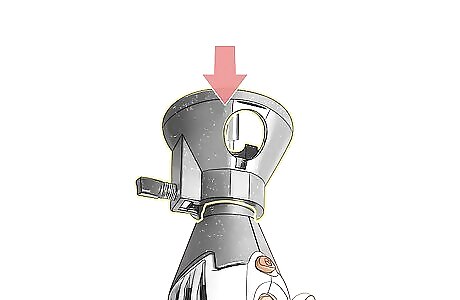

Attach the bit you chose to the end of the router. Unscrew the circular guard from the bottom of the router so you can access the bit mechanism. Use a wrench to loosen the bolt holding the bit in place and pull it out from the router. Place the end of the new bit in the hole at the bottom of the router, and retighten the bolt with your wrench. Line the guard back up on the router and secure it back in place. You can buy a router from your local hardware or home improvement store. Consult your router’s user manual if you don’t know how to change the bit. Some guards have a quick-release lever on the side of the router so you don’t have to unscrew it.

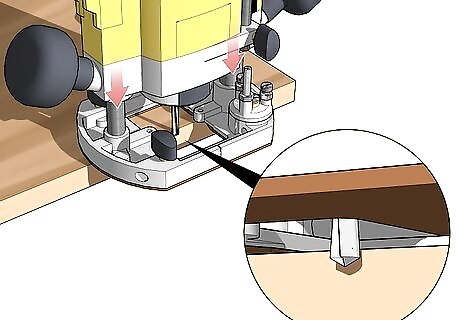

Set the depth of the router to match how deep you want the groove. Look for the depth adjustment dial on the side of the router or on the guard. Set the router on a piece of scrap wood so the bit just hangs over the edge. Turn the adjustment dial to raise or lower the bit to the depth you want. Check how far down the bit goes on the side of the wood, and lock it in place once you have it set. The adjustment dial usually has depth measurements printed on it, but check the bit depth with a ruler to ensure that it’s correct.

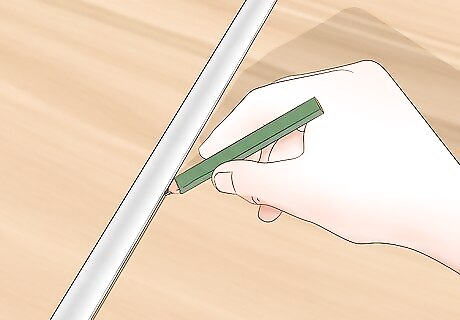

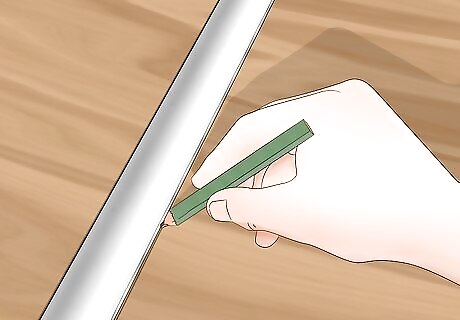

Mark a line on the wood where you want to place the groove. Hold a straightedge against the piece of wood you’re cutting, and use it as a guide to draw a straight line for the groove. Double check the measurements for the groove you’re cutting so it’s not too long or short. If you’re making curved grooves in the wood, either trace the edge of a rounded object or use a compass to draw your lines.

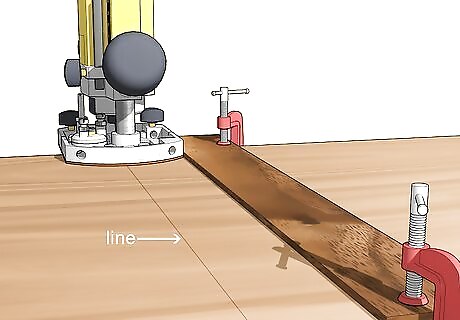

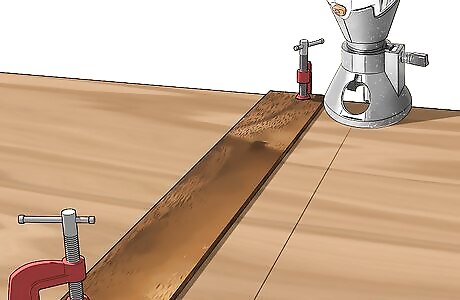

Secure a piece of scrap wood on top of the wood you’re cutting. It can be difficult to carve a straight groove in your wood if you’re trying it freehand. Set your router on the wood so the bit lines up with the line you drew. Set a flat piece of scrap wood on top of the piece you’re cutting so it touches the router guard. Ensure that the side of the scrap wood runs parallel with the line you drew before securing the scrap piece with a C-clamp. If you want to cut a curved groove, you can either try routing it without using a guide, or you can buy a curved guide from your local hardware store. Secure the curved guide to the piece of wood you’re carving with a C-clamp.Tip: Use a clamp every 12–18 inches (30–46 cm) so the wood doesn’t move or lift up while you’re working.

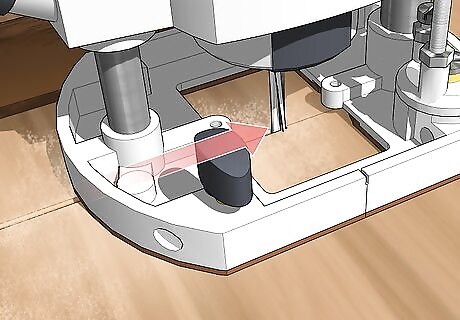

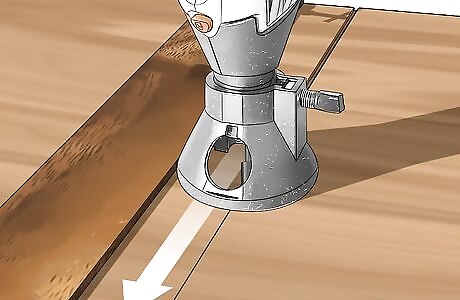

Pull the router along the line to make the groove. Wear safety glasses while you’re working so to protect your eyes from wood pieces. Place the router at the end of the line you drew so the guard pressed up against the clamped piece of wood. Turn on the router and pull the plunge lever down so the bit goes into the wood. Slowly pull the router toward you along the line to cut into the wood. Keep the side of the guard against the clamped wood to ensure the groove stays straight. The router may tear out some of the wood when you first start and stop running the machine. If you want to prevent tear out, start and end the router in scrap pieces of wood butted up against the piece you’re cutting. Routers can produce a lot of sawdust, so keep a shop vacuum nearby so you can easily clean up when you’re finished. Some routers even have ports that you can directly attach a vacuum hose to. Norm Abram Norm Abram, Master Carpenter Cutting neat grooves in wood takes precision and knowing how the material reacts. No matter the tool — circular saw, router, chisel — measure twice, cut once. With a circular saw, use a guide rail for straight, steady grooves. Chisels need sharp blades and a steady hand. In woodworking, beauty's in the details - every tiny groove matters, structurally and visually. Rushing it risks ugly mistakes. Be patient, mind the wood grain.

Routing with a Rotary Tool

Choose a routing bit to install on your rotary tool. Rotary tools are handheld tools that have a rotating head that you can attach multipurpose bits to for many different projects. Look for groove-cutting router bits for your rotary tool and check which shape they carve out of the wood. Bits that have a pointed end usually leave V-shaped grooves while flat-bottomed bits leave a flat groove. Loosen the bolt on the bottom of the rotary tool and slide the bit into the hole. Tighten the bolt to secure the bit in place. Most rotary tools come with a set of bits, but you can buy additional bits from hardware stores or online.

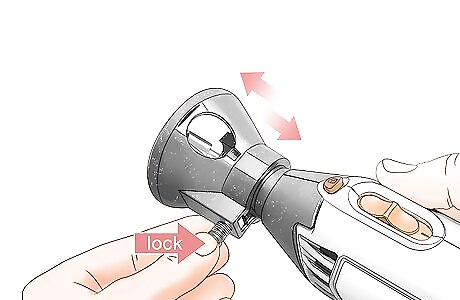

Secure a spiral cutter attachment to the end of the rotary tool. A spiral cutter attachment is a circular guard that goes around the bit so you can hold it flush against your piece of wood. Slide the spiral cutter over the end of the bit and screw it onto the threading. Make sure the spiral cutter attachment is tight against the tool’s body so it doesn’t come loose. You can get a spiral cutter attachment from your local hardware store or online.

Draw the groove you want to cut on the piece of wood. Use a straightedge as a guide for making your line to ensure that it doesn’t get crooked. Line up the straightedge with the area you want to cut and draw a guide line directly on the piece of wood you’re cutting the channel into. Check your measurements once or twice to ensure they’re correct before moving on. If you want to make a curved line instead, trace around a curved guide template or draw the curve with a compass.Tip: Rotary tools work best for cutting grooves that are 12 inches (30 cm) or less since the tool isn’t as powerful as a router.

Adjust the gauge of the spiral cutter to the depth you want for the groove. The gauge on the spiral cutter controls how deep the routing bit sticks out from the bottom of the tool. Loosen the wingnut on the side of the spiral cutter so you can pull the gauge up or down to raise or lower the bit. Adjust the gauge until the measurement printed on the side is the same as the groove depth you want. Tighten the wingnut to secure the bit in place. You can hold the rotary tool on the piece of wood you’re cutting to see how far the bit hangs over the edge. If you aren’t sure how to adjust the depth on your spiral cutter attachment, consult the user manual for help.

Clamp a piece of scrap wood on top of the piece you’re cutting as a guide. You can cut your groove freehand if you want, but the line may be crooked when you’re finished. If you want to ensure the groove stays straight, set a piece of scrap wood next to the line you drew. Set the rotary tool on top of the line and move the scrap wood over so it touches the spiral cutter. Use C-clamps to secure the wood in place every 12 inches (30 cm). Make sure the scrap wood you’re using has a flat edge, or else the groove may cut unevenly. You may also use a saw fence as a guide if you have one available. If you want to make a curved groove in the wood, then secure a curve guide to your wood with a C-clamp. You can buy curve guides from your local hardware store.

Run the rotary tool along the line you drew to cut the groove. Wear safety glasses so you don’t get sawdust in your eyes while you’re working. Start the rotary tool at the edge of the wood you’re cutting and turn it on so the bit gets up to full speed. Push the rotary tool along the line so the spiral cutter stays against the guide board you clamped down. Once you reach the end of your line, turn the tool off before pulling it away from the wood. Don’t take the rotary tool out of the wood while it’s still running or else you could make an accidental cut or make your groove crooked. Never touch the bit on the rotary tool while the machine is running, or else you could severely injure yourself.

Cutting Grooves with a Table Saw

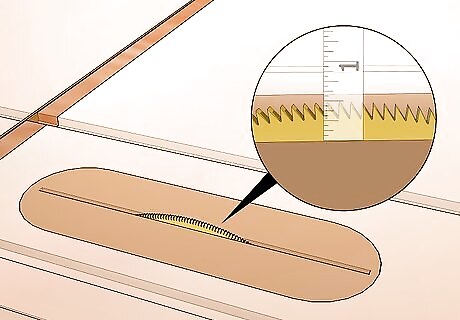

Set the blade height of your table saw to the groove depth you want. Hold a ruler next to the saw blade so you can see its height. Use the knob or lever underneath the table saw to raise or lower the height of the blade until it’s at the depth you want to cut for your grooves. Secure the blade height so it doesn’t move around or slip while you’re working. You won’t have a blade guard on your saw when you cut grooves, so be extra cautious while running the machine so you don’t cut yourself. Table saws work best for cutting long, straight grooves in planks of wood.Tip: You can use any saw blade made for wood to cut your grooves, but a flat-edged saw will leave a flat bottom while angled blades leave a rounded edge.

Mark the groove on the side of your wood. Set the piece of wood on its side so the face you’re cutting the groove into faces up. Use a ruler or straightedge to make a straight line on the side of the board that’s the same length as the depth you want for your groove. Once you mark one end of the board, mark the opposite end of the board in the same place so you can line up your cut. Table saws don’t work well for cutting grooves in large pieces of plywood since you won’t be able to see where the cut lines up very well.

Adjust the saw fence so the mark on your wood lines up with the saw blade. Hold the piece of wood against the saw fence so it’s snug. Loosen the saw fence so you’re able to move it and adjust it closer or further away from the saw blade. Keep moving the fence until the mark you made on the side of your board lines up with the edge of the saw blade. Tighten the fence in place so it doesn’t move around while you’re working. If your table saw doesn’t have a fence, then secure a straight piece of scrap wood on the side of the blade instead. You can also clamp a board on the other side of the saw blade if you want to ensure the wood you’re cutting doesn’t move or shift.

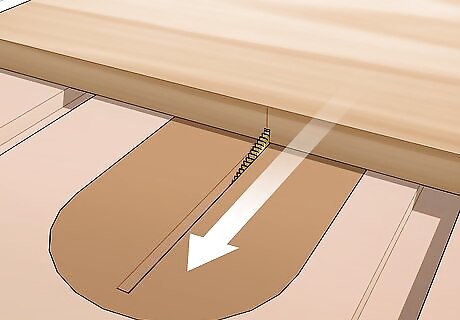

Push the wood through the saw blade to cut the groove. Wear safety glasses before you start working since saws can kick up wood bits or sawdust. Turn on the table saw and let it get up to full speed before you start your cut. Slowly push the board through the saw using a wood pusher, which is a tool you hold onto to guide the wood so your fingers are away from the blade. Push the wood completely through the saw blade before turning it off. Never try to grab your wood until you turn the blade off, or else you could accidentally cut yourself. Don’t push the wood through the blade without a pusher since you could get seriously injured if you’re cut by the saw.

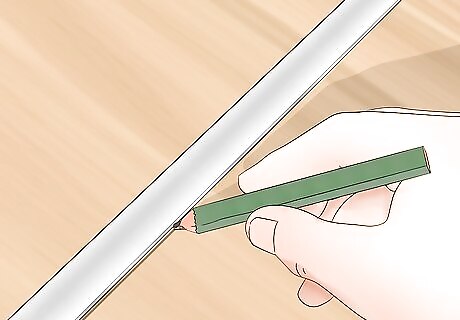

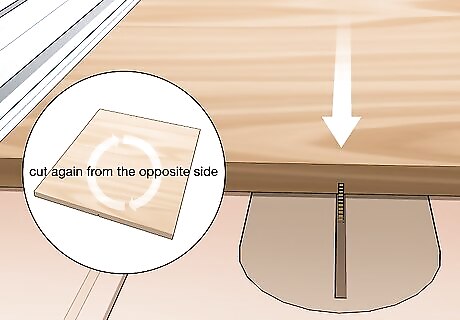

Run the wood through the saw again starting on the opposite side. To make the groove look even, you need to run the wood through the saw again starting from the other side. Turn the piece of wood around so you’re feeding it backward into the saw. Start the blade again and push the wood completely through the saw. Stop the saw so you can check the groove. If the groove is too small, move the saw fence ⁄8 inch (0.32 cm) away from the blade to widen the groove.

Comments

0 comment