views

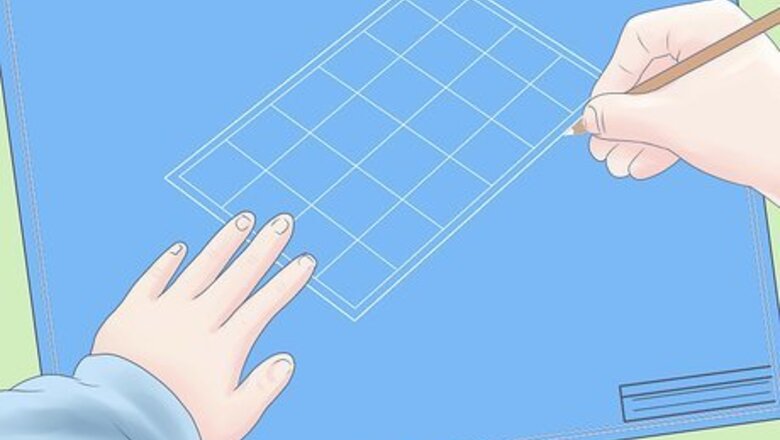

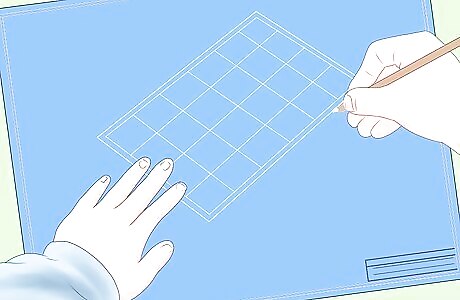

Plan your work. A drawing of your design is very helpful. It allows you to create a pattern you like and determine how much tile you will need and in what colors. Graph paper is perfect for this or you can create your design with a drawing program. Take a trip to your local tile store and find the tile you like first, then create your design. You'll also need some tools and materials which listed elsewhere in this article.

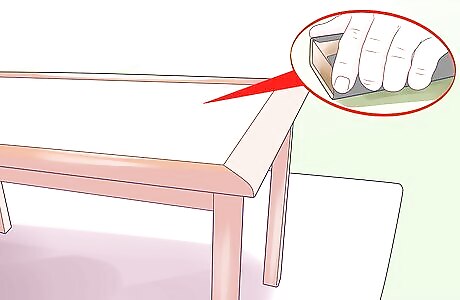

Place your table over the drop cloth. Remove the old finish or at least rough it up with sandpaper. Take your coarse grit sandpaper and work the finish good. The objective is to create a rough surface for your thinset mortar to grab onto. Unlike finish woodworking, a smooth surface is NOT the objective. If you do not have sandpaper in your home kit, look into a sanding block at your hardware store. These are stiff foam covered with various grades of sandpaper and work like a champ. If you do have sandpaper, wrap it around an old chalk eraser to get a better grip and save your hands. A small block of wood also serves but the eraser is more comfortable.

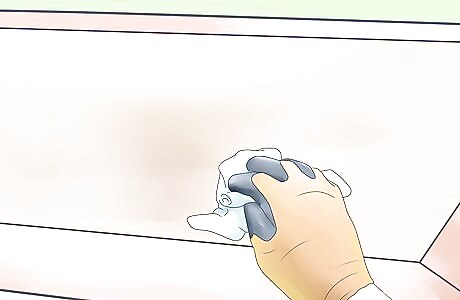

With a damp cloth, wipe off all the sawdust.

Now is the time to inspect the surface for potential problems. If you have large cracks or the table is made of several independent pieces such as a picnic table, consider an underlayment that will span these cracks. Why? Movement of the wood can cause your tiles to crack. Schluter Ditra makes one such product. But, it may not be available in the small quantity you need. Another option, and the one I will use for this project, is simple Masonite, 1/8" to 1/4" thick.

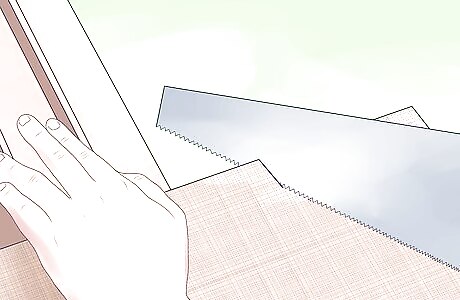

Cut the Masonite to fit your table. If you do not have a proper saw for the project, take your table measurements with you to the hardware store and ask them to cut it for you.

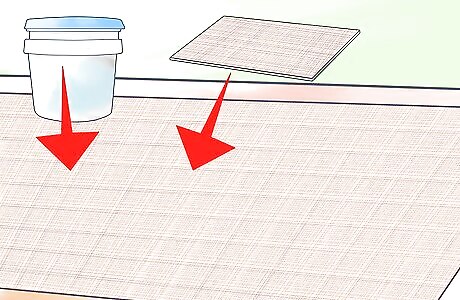

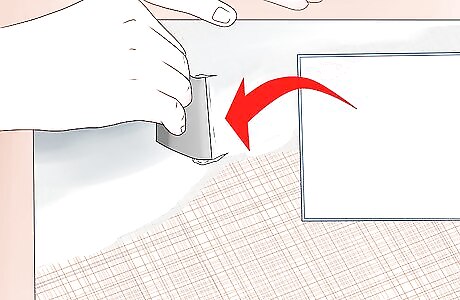

Using the same thinset mortar that you will use for your tile, cover the table top. Place the Masonite on the thinset, smooth side down and apply a light even pressure over the entire surface. A rolling pin makes a nice tool for this purpose. Clean excess thinset from the edges of the table.

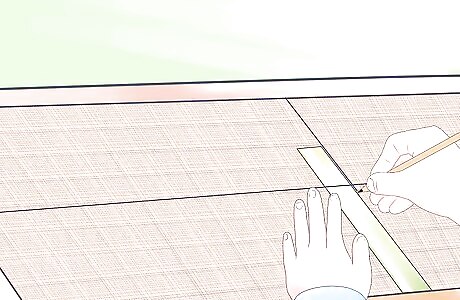

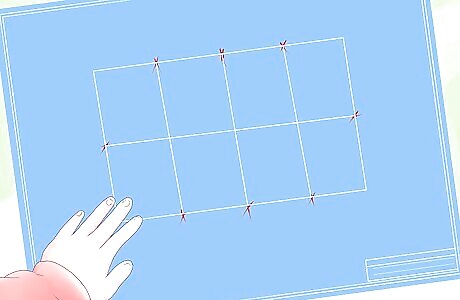

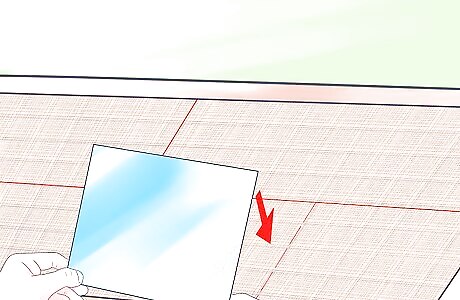

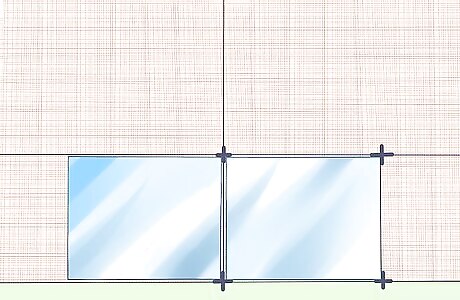

Grab your design and lay your pattern out on the floor. This step allows you to make adjustments to your design and to get a feel for how it will look. With a ruler and your pencil, draw a line to divide the Masonite down the center and across its middle so you have four equal squares or rectangles.

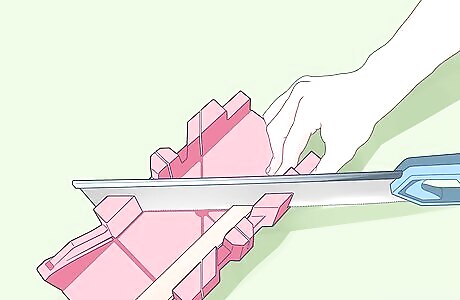

You are now into the most critical portion of the project - laying out, cutting and setting the tile. For new tilers, develop a design that does not require cutting. You can accomplish this with the size tile you buy and the width of your grout lines. This said, you learn by doing so if your design does not allow for full tile only, rent a tile saw for the project. Most tile stores offer them for rent. For this project, it is assumed there's a symmetrical layout that flows along the two lines you drew and does not require cutting. A tutorial on cutting tile is available here:How to Cut Tile.

Some tilers prefer to put their thinset mortar on the surface they are tiling and place the tiles into the mortar. They do this by spreading the thinset over a small area of the project and placing the tiles onto the mortar. You must be careful not to apply the thinset over such a large area that it dries out before you get to it.

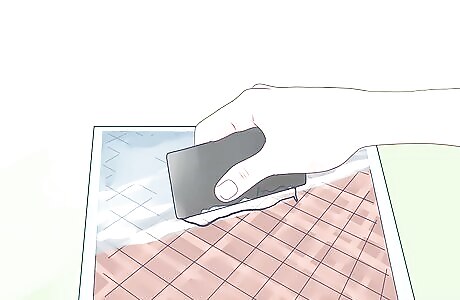

An alternative approach is called "buttering" the tile. Sounds appetizing, doesn't it? This technique has you take some thinset, apply it to the back of a tile like you are spreading it with a butter knife then spread it over the entire tile back with your notched trowel. Take a regular trowel, grab some thinset with it and scrap it onto the tile at one edge. Take your notched trowel and spread it across the tile then run the trowel over it again at a 90 degree angle. The objective is a smooth, even and complete covering of the back of the tile. Thickness is important here. You want each tile to have a consistent thickness of mortar for an even top later but you don't want it so thin that you have poor adhesion. Have enough so that when you have made my two passes with the notched trowel, you cannot see any of the back of the tile and the total thickness of the mortar is the depth of the notches plus about 1/8".

Place your "buttered" tile on the Masonite at the center where your two lines intersect. With a modest amount of pressure, wiggle the tile horizontally so you seat it firmly onto the Masonite. The buttered tile approach has two benefits - no dried out mortar and you can always see your lines that guide tile placement.

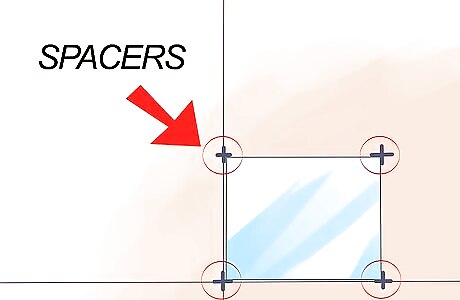

To help to keep your tile spacing even, place three of the tile spacers at the same time you set your first tile. These little plastic plus signs should go at the corner where the tile meets the two intersecting lines and at the corners of the tile along the other lines. Span the lines with the spaces so the line goes through the center of the spacer. If you are using a butted pattern where you have no grout joints, simply line up the edges of your tile along the lines you drew.

At this point, things will really start to roll. Work your tiles as described in the buttered step and place them firmly, adding in your tile spacers. You can without the spacers but they make life a lot easier and make your grout joints much more precise. As you reach the edges of your table, be sure to remove all the thinset from the edges so you have a clean edge for your molding later.

If your design calls for a grout joint all the way around the edge of the table, this is the time to attach the edge molding. Before you begin, allow the tiles to set. Your thinset mortar instructions will tell you how long.

On a project like this, use a simple batten. This is a flat piece of wood about 1/4" thick and wide enough (tall, if you prefer) to cover the entire edge of the table and the thickness of the tile. For example, if your tile is 3/8" thick and your table is 1.5" thick, you would need a strip 1 7/8" wide. If a 2" piece is more readily available, that is fine, allow the excess to project below the bottom of the table top.

Attaching the edge molding requires some thought on how you want it to look. The most precise method is to miter the corners like a picture frame. For this you need a miter box and saw. Since this can be tricky (and frustrating), let's use an easier method.

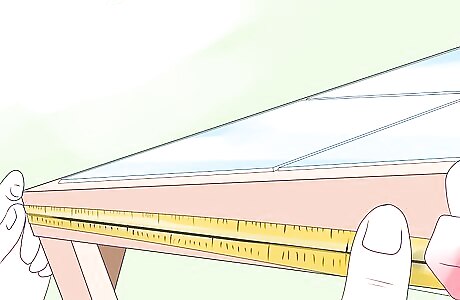

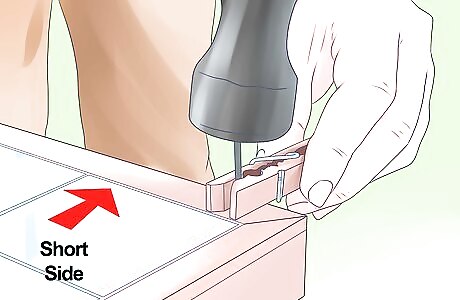

Measure the short end of your table and add the thickness of your molding. Mark this carefully on your molding. Take the marked piece and hold it along the short edge of the table with the end flush to the side. Make sure the mark you made is at least the thickness of the molding beyond the other edge of the table. It can be longer but not shorter. Carefully cut the molding. Start one of the finishing nails about 1" for the end of the molding in the center of the molding (but low enough to not hit your tile). Hold the molding along the short end of the table so that it's top is level with the top of the tile. Use masking tape to hold the molding in position. Drive the nail halfway into the table.

Using a straight edge, check to be sure the molding is level all along the edge of the table. Add another nail at the center of the molding, driving it in halfway. Check your level then add a third nail at the far end of the molding. If all is level, drive the nails all the way in. Hammer carefully as you do not want to dent the molding. Add more nails so that you have them spaced about 6" apart. Have an eye for a pattern as you go. Using the nail set, drive the nails slightly below the surface of the molding. You will fill in over them with wood filler later.

You will repeat this process on the long side of the table next. Butt the end of the molding next to the molding that overhangs the edge of the table. Holding it in place (again, masking tape works well), measure so that the molding has a similar overhang at the other end. Mark your molding and cut carefully. Remember, a little too long is fine - a little too short is not. Carefully cut the molding, start a nail and proceed to attach it along the long side of your table as in the preceding step. Repeat this for the remaining two sides.

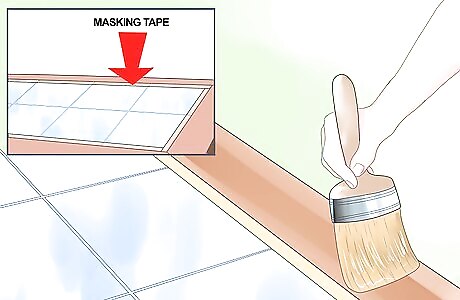

Finish this phase by putting masking tape along the top edge of your molding. This will protect it during the grouting process. The tape should not interfere with the grout area, being exactly even with the inner edge of the molding. Fold the excess down the outside face of the molding.

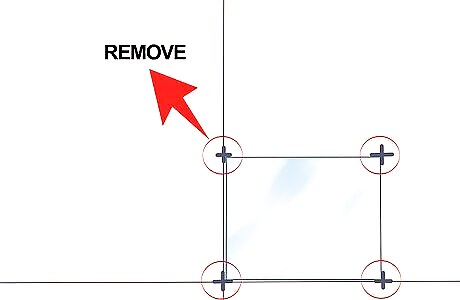

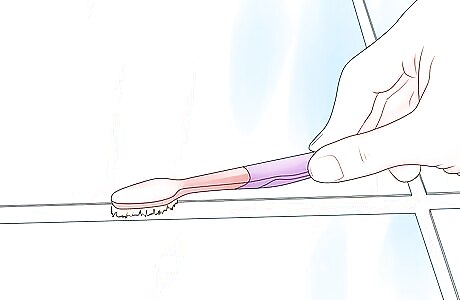

Okay, you are ready to grout. Step number one here is to remove the tile spacers. They may stick. If so, use a sharp, pointed object like a straight pin or knife to grab then and pry them out. You can save them for future projects.

Your grout will either be sanded or not, depending upon the width of your grout joint and the type of tile you are using. Consult with your tile seller for specific recommendations. It is possible to scratch a glossy tile with a sanded grout so choose wisely. Plus, sanded grout can scratch your edge molding or stain it (hence the masking tape treatment in the preceding step).

Mix the grout to a fairly stiff consistency, something like a batter. If it is too wet, it has less strength. If it is too dry, you cannot work it into the grout joints. When the grout is the proper consistency, trowel a goodly size amount onto the tile surface and work it into the joints with the squeegee / float. Use even pressure and steady strokes to be sure you fill the joints completely. Squeegee off excess.

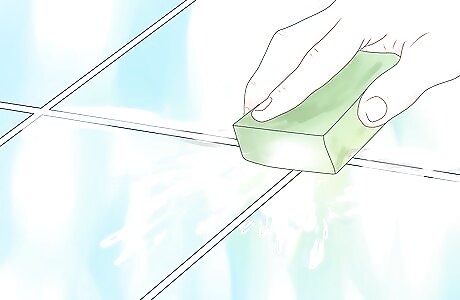

Next, dampen your sponge and wipe off as much excess grout as possible. Be careful here that your sponge is not too wet as it will strip out too much grout. Most tile has a slight bevel or drop around the edges where the finished surface drops down to the raw tile edge. Keep the grout right at that level so it is slightly below the surface of the tile.

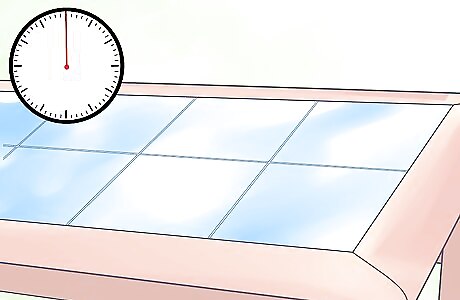

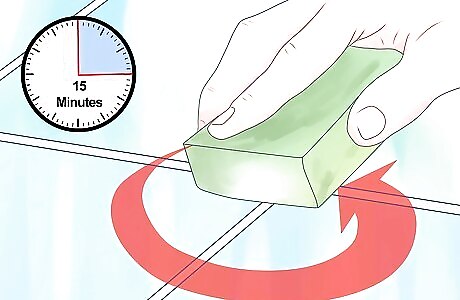

Now you need to exercise a little patience and let the grout set up somewhat. After about 15 minutes, take your damp (not wet) sponge and using a circular motion, start cleaning the tile surface. This is where you can add some profile to the grout joint by how you smooth it out. Use a slight bit more pressure along the joint to make is concave and get it to the level you want relative to the tile.

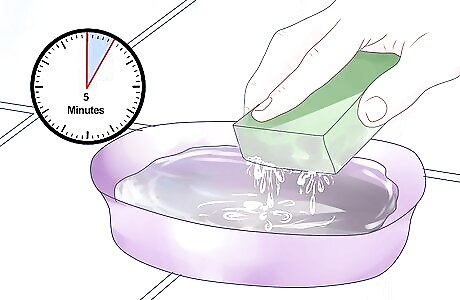

Rinse your sponge often. If you see the grout smearing heavily when you wipe with your sponge, give it another five minutes. This may be the most tedious stage as there seems to be an endless amount of the dull grout residue. Your goal is to get your grout lines where you like them and remove most of the grout and its haze.

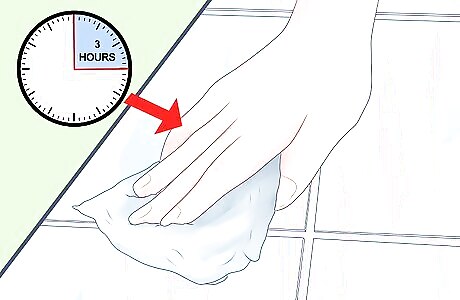

Let it set for a few hours then finish the wipe down process. Use a dry towel in between wipes with the sponge to remove the haze. Note: The grout will have excellent directions about the timing of all this so follow their guidelines for best results.

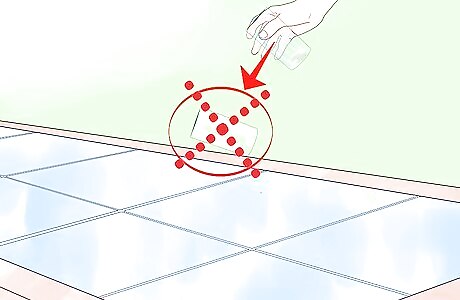

Almost there! With your spanking new tile surface and fresh grout joints, it is time to seal the joints. You can try everything from flooding the whole surface and spreading the sealer with a disposal sponge brush to carefully applying it to just the grout itself. Your technique will depend upon how you want to proceed. If you need to seal your tile as well as your grout, do the tile first so you have no risk of staining the tile with the grout sealer. It isn't a stain so much as a difference in color as you have sealed the small portion around the joint before the rest of the tile and that might be hard to reverse.

Apply as many coats as recommended, more for an outdoor table. Let this dry overnight.

The last step is to finish your edge molding. Remove the masking tape and apply a reverse treatment to your table's top. You want to protect the grout and tile from your finish applied to the molding. Tape carefully along the edge between the grout and the molding so that no grout is showing. At the corners of the table, use a knife or razor blade to get a nice square end. Carefully stain the molding and let it dry.

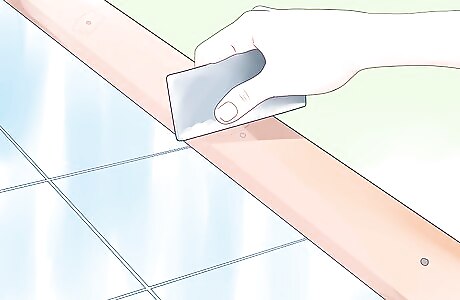

Check your corners where the molding butted together. You should have a nice square joint with not excess molding. If there is a bit of excess, carefully sand it down with a fine sandpaper, say 100 grit.

If you used the nail versus adhesive attachment method, fill the nail holes with wood filler. With a putty knife, wipe off the excess. Some filler is water based and can be wiped off with a damp paper towel. Approach this like your grout clean up – not too wet! Sand it smooth with 200 grit sandpaper or fine steel wool. Wipe down the molding with a slightly damp paper towel and let it dry.

One thing to consider here is the use of a stain and top coat combined. Minwax makes a nice product as do other manufacturers. This saves you the step of putting the clear finish over the stain. If you are going to use your table outside, do NOT go this route. You can also simply use a good grade paste wax (non-automotive) over the stain or an oil finish such as linseed. This depends upon the look you want and where it will be used.

Congratulations! Your new tiled table is ready for its grand debut. Adorn it with snacks and drinks, invite over some friends and show off your handiwork. After all, it’s the satisfaction of a job well done being well appreciated that counts, right?

Just remember, nothing bounces on tile like it might on a wood table so glasses will almost always break - a small price to pay for a fine tile table.

Comments

0 comment