views

Part One: Winding the Bobbin

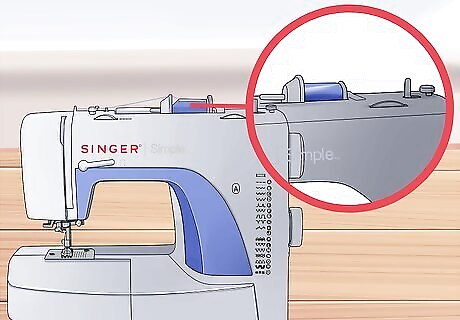

Position the spool of thread. Place the spool of thread on the spool pin at the top of the machine. Hold it in place by slipping the spool holder onto the pin, as well. If you are using a small spool of thread, place the cap on the pin so that the small side is next to the spool.

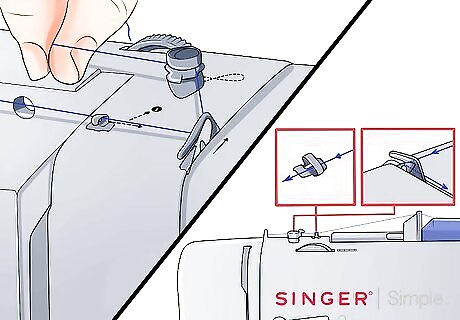

Guide the thread. Feed the thread through the thread guides and around the bobbin winder tension discs. Snap the thread into the small plastic thread guide lying directly to the left of the spool pin. With the thread held in place by the thread guide, wind the thread clockwise around the bobbin winder tension discs in front of the guide.

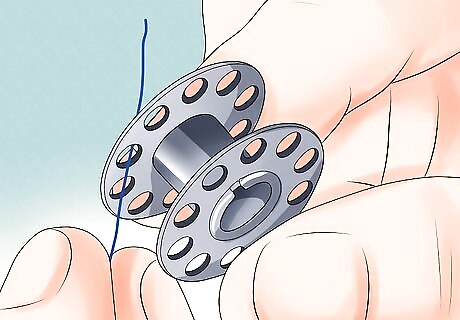

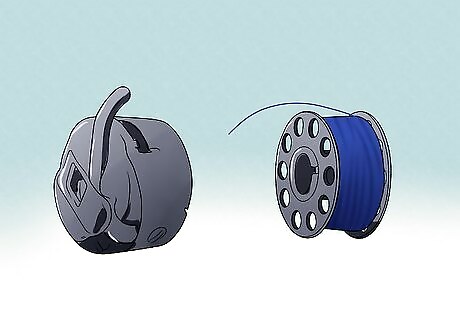

Feed the thread through the bobbin eye. Insert the thread through the top hole of the empty bobbin spool. Feed the thread through from the inside so that the tail is still on the outside of the bobbin. If you're using a bobbin with holes on both sides, only slip the thread through one hole.

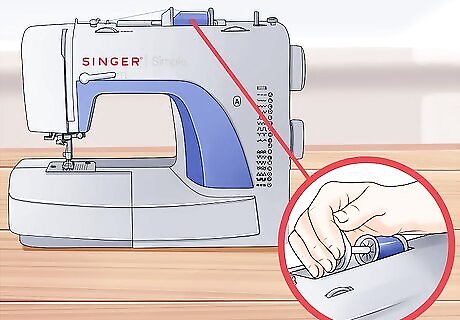

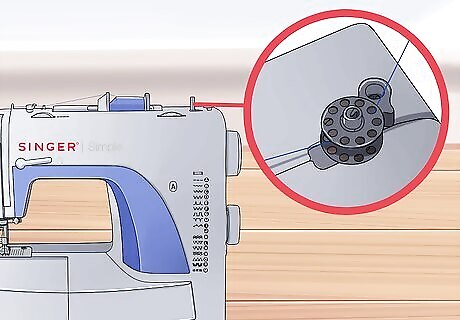

Set the bobbin in place. Place the bobbin on the bobbin winding spindle, located to the far right of the machine. Lock the spindle in place. The tail of thread should still stick out through the top of the bobbin. To lock the spindle in place, push the bobbin as far to the right as it will go. This sets the machine to its "bobbin winding" mode.

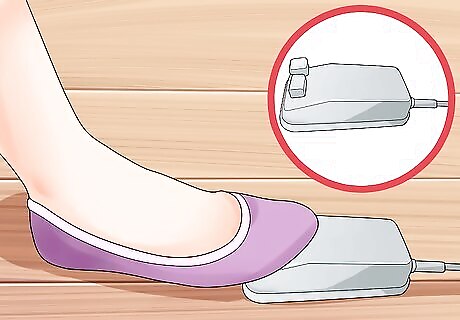

Step on the foot control pedal. Hold the thread tail and gently step on the foot control pedal. The machine should begin to wind the bobbin. If desired, you can let go of the thread tail after the bobbin has wound a few rotations, but doing so is not necessary. The machine should automatically stop once the bobbin is full. Note that the hand wheel should not turn and the machine should not sew while the machine is in its bobbin winding mode.

Remove the finished bobbin. Cut the thread to separate the bobbin from the spool. Unlock the bobbin winding spindle and lift the bobbin away to remove it. Unlock the spindle by pushing it back to the left. Note that the machine will not sew until the bobbin winding spindle is back in its left position. You should also trim the tail of thread sticking out from the top bobbin hole after removing the bobbin.

Part Two: Threading the Needle

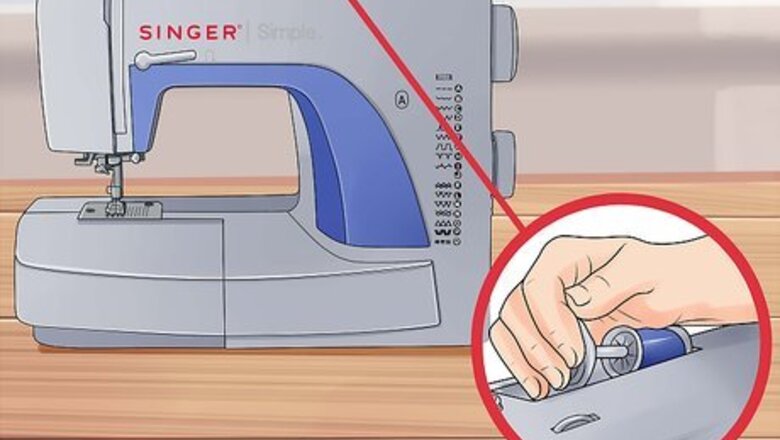

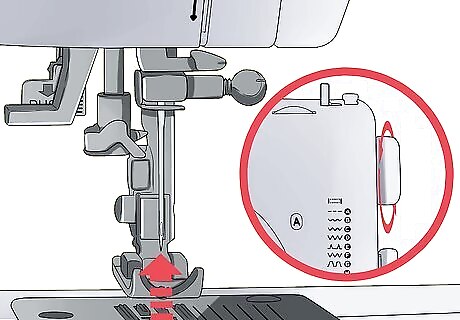

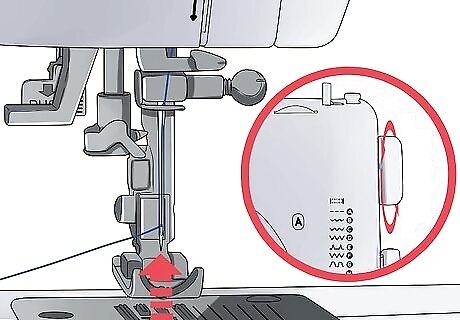

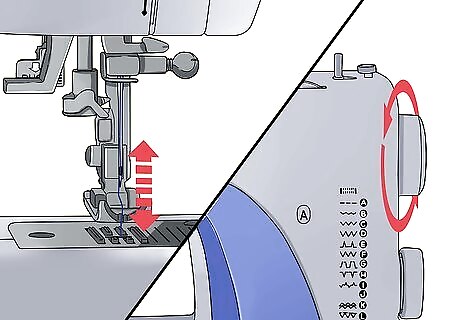

Raise the needle. Turn the hand wheel at the side of the machine until the needle reaches its highest point. Turn the machine off before threading the needle. Rotate the hand wheel toward you. Raise the presser foot to release the tension discs at this time, as well.

Position the spool. Place the spool of thread on the spool pin at the top of the machine. Fit the spool cap on the pin next to the spool of thread. You'll need to lift up the spool pin before you can position the spool of thread on it. For larger spools, the large side of the cap should face the spool. For smaller spools, the small side of the cap should face the spool.

Feed the thread through the upper guides. Draw the thread through the upper thread guide, then guide it around the guide an through the pre-tension spring. The upper thread guide is a latch lying to the left of the spool pin. The pre-tension spring lies inside of a second latch positioned in front of the upper thread guide.

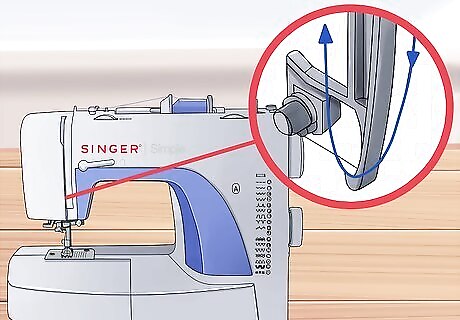

Thread the tension module. Guide the thread down through the right channel at the front of the machine, then back up through the left channel. You may need to pinch or hold the thread between the spool and the upper thread guide while doing this to maintain an appropriate amount of tension.

Feed the thread into the take-up lever. Slide the thread into the slot of the take-up lever at the top of the left channel. After inserting the thread through the take-up lever, pull it back down through the left channel again.

Pass the thread through the lower guides. Guide the thread through the horizontal lower thread guide and into the thin wire clamp guide. The horizontal thread guide is a flat clip lying beneath the left channel. The thin wire needle clamp is positioned directly above the needle.

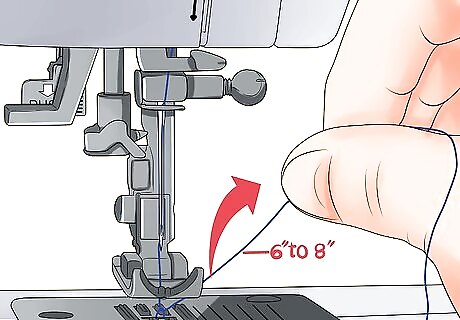

Thread the needle. Feed the thread through the eye of the needle, inserting it from front to back. Pull 6 to 8 inches (15.25 to 20.3 cm) of thread through to the back of the needle.

Part Three: Using an Automatic Threader

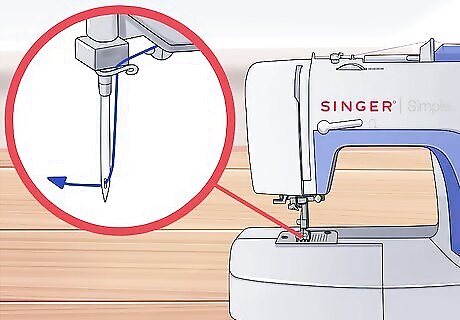

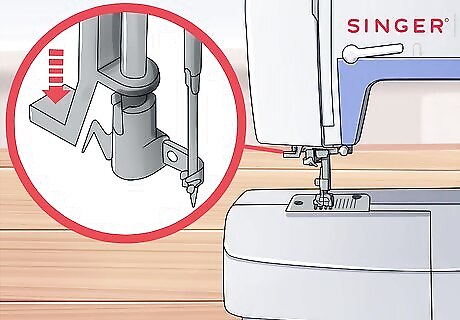

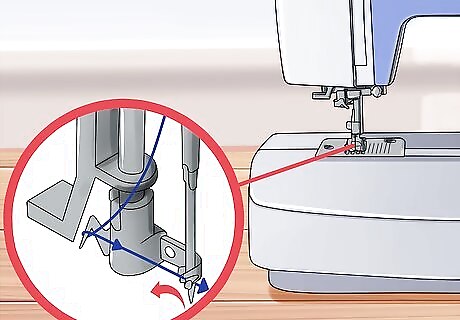

Press the automatic threading lever. Press this lever down as far as it will go. The threader should swing into its threading position. This lever should be located to the left of the needle. Note that these instructions only apply to models of the machine equipped with an automatic needle threader. Standard needle threading instructions still apply when you use an automatic threader. This feature only assists you with inserting the thread through the eye of the needle; the rest of the process should be treated exactly the same way. Even if your machine has this feature, you can still thread the needle by inserting it through the eye without assistance. This feature is only optional.

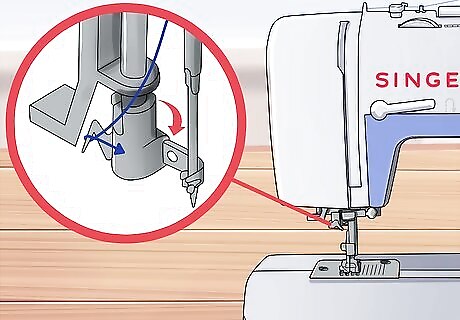

Direct the thread through the thread guide. Swing the thread down and around the thread guide hook to the left of the needle.

Position the thread in front of the needle. Drag the thread through the hook lying directly to the right of the needle. After inserting it through the hook, wrap the thread around that hook from bottom to top.

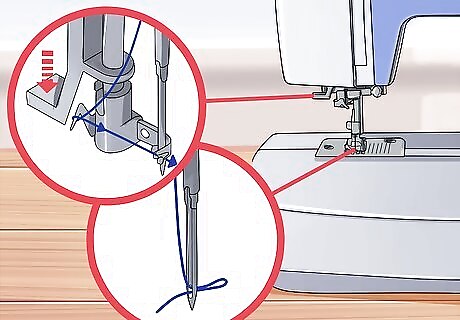

Release the lever and pull the thread. Push the threading lever back up to release the automatic threading system. In doing so, you should cause a loop of thread to swing into the eye of the needle. Grab that loop of thread and pull it through to the back of the needle. Pull 6 to 8 inches (15.25 to 20.3 cm) of thread through the eye.

Part Four: Inserting the Bobbin

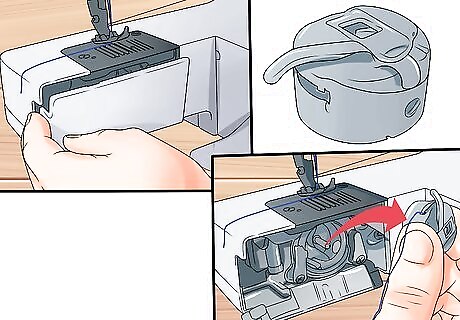

Lift the needle. Turn the hand wheel at the side of the machine toward you until the needle reaches its highest position. Make sure that the machine is off while you insert the bobbin.

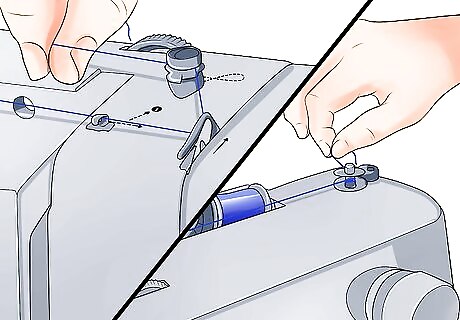

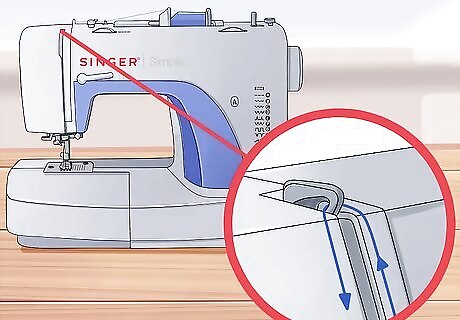

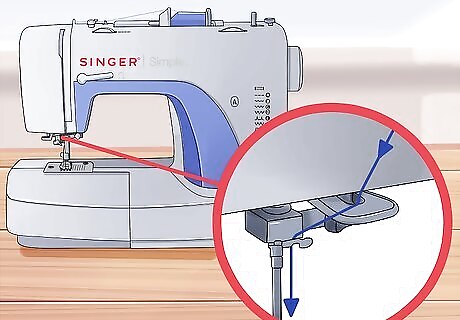

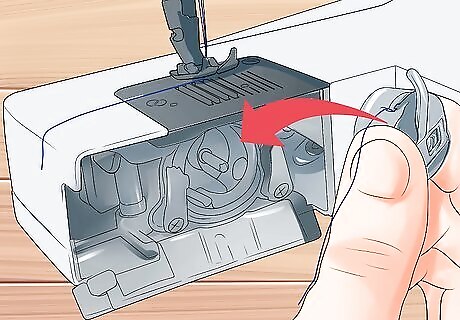

Remove the bobbin case. Open the hinged cover at the front of the machine and pull the bobbin case straight out. To open the cover, grab it along the side and push it down. The cover will open but will not detach. To remove the bobbin case, pull on the bobbin case tab and lift the case straight toward you.

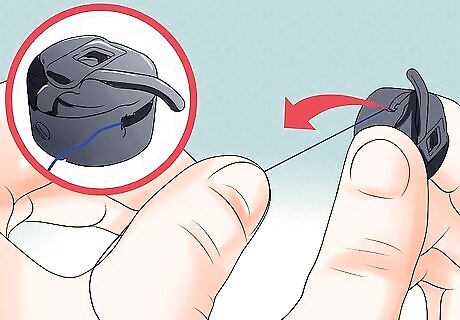

Insert the bobbin into the case. Hold the bobbin case with one hand while slipping the wound bobbin into the case with the other. The thread should run in a clockwise direction around the bobbin as you insert it into the case. Keep a tail of thread roughly 4 inches (10 cm) long out of the case as you insert the bobbin.

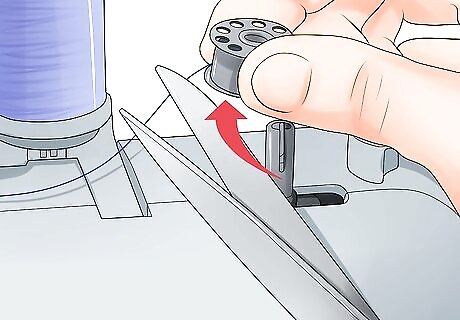

Pull the thread through the slit. Grab the remaining tail of thread and pull it through the slit at the top of the bobbin case. Continue sliding the thread through that slit until it slips under the finger of the case.

Return the bobbin case to the machine. Hold the loaded bobbin case by its hinged latch and slip it back into its place in the machine. Release the latch. If the case has been positioned correctly, it should be secure inside the machine. You should not be able to remove it unless you lift the hinged latch again. Close the cover when done by pushing it back up and into place.

Part Five: Raising the Bobbin Thread

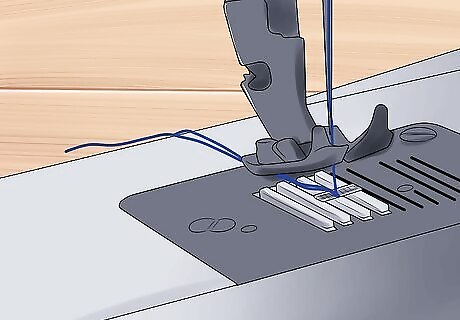

Rotate the needle. Turn the hand wheel at the side of the machine toward you. Continue until the needle goes through a full rotation, lowering into the machine and rising back out to its highest position. For the sake of safety, it is best to do this while the machine is off. The presser foot should also be raised during this procedure. As you turn the wheel, you should see a loop of thread appear through the needle plate hole beneath the needle. This loop of thread is from the bobbin.

Pull up the lower thread loop. Gently tug on the upper thread to release the loop and bring the lower bobbin thread completely through the needle plate hole. Pull 6 to 8 inches (15.25 to 20.3 cm) of bobbin thread out through the plate.

Arrange both threads. Position both threads so that they lie toward the back of the machine. Both threads must pass beneath the pressure foot. The upper thread will need to slide through the "toes" of the pressure foot. The completion of this step marks the completion of the entire threading process.

Comments

0 comment