views

Assembling Your Sink

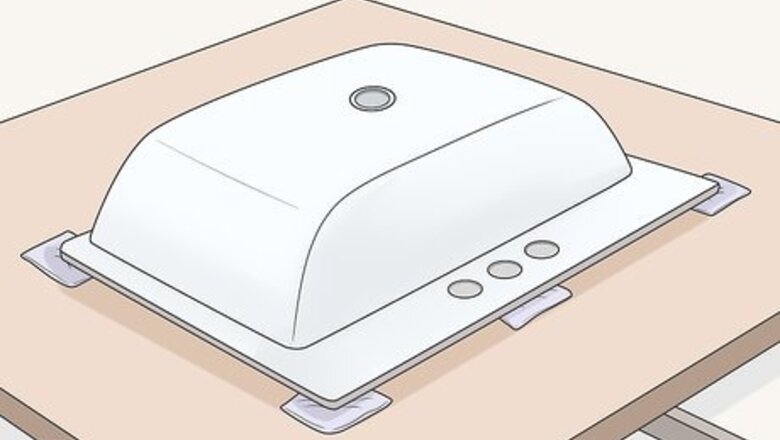

Set the top upside down on a table or sawhorses. You need a really stable surface to work on, so either set two sawhorses up and place the countertop on top or find a really strong table. Be mindful that if you drop your vanity’s top on a hard surface, it can shatter or crack. To avoid cracking it, grab 5-10 rags or cloths and set them under the sink as you lay it upside down on your work surface.Tip: Most vanities come with the sink assembly designed to fit the countertop. If it doesn’t though, you’ll have to buy a sink assembly separately. Measure the diameter of the opening at the top and the bottom to determine the size of the flanges and gaskets you need. Some vanities come with the sink’s supply tubing and pipes preassembled. If this is the case with your sink, you’ll be able to skip this set of steps entirely. This process is exceptionally hard to do if you install the countertop on the vanity before assembling your sink.

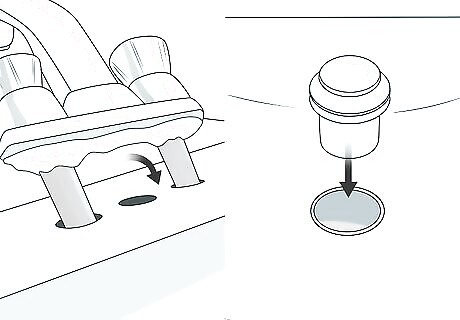

Run plumber’s putty along the interior rim of the sink flange. Get a can of plumbers putty and pull a piece out by hand. The amount of putty you need is roughly the size of your palm. Mold the putty into a thin 5–6 in (13–15 cm) length by rubbing it together. Wrap the putty around the bottom lip of the sink flange and press it firmly around the edges. The plumber’s putty will hold in place while you assemble the rest of your sink. Plumber’s putty smells kind of strong, but it’s not dangerous to touch. You can mold it in your hand without a glove and just wash your hands off after. The sink flange is the shiny metal piece that goes in the bottom of your sink bowl. It will be the only piece of your assembly with a finish and you’ll see threading in the inside towards the bottom. Plumber’s putty takes a long time to dry, so don’t worry about your putty hardening while you work.

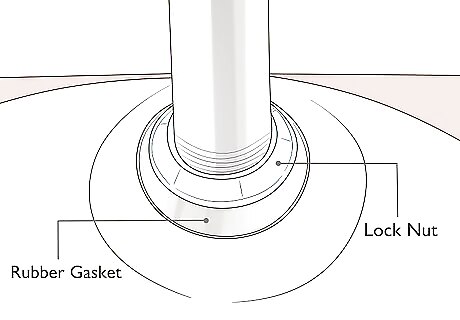

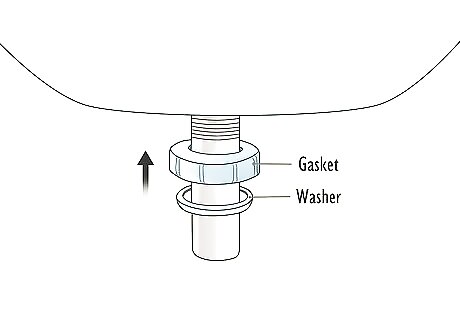

Thread the rubber gasket over the lock nut on the drain pipe. The drain pipe is the metal pipe that runs from the sink flange to the pipes underneath the vanity. It will have one end with threading and one end without threading and a small lip in the middle. Hold the pipe with the threading at the top. Slide the metal lock nut over the pipe and let it fall to the lip. Slide the rubber gasket on top of the lock nut. When you assemble the drain pipe, the lock nut will screw into the threading on the drain pipe and compress the rubber gasket into the base of the sink to create a waterproof seal. You may have a third or fourth gasket to slide over the rubber gasket. Follow the manufacturer’s instructions to complete the assembly. Some sinks have no drain pipe assembly whatsoever and only screw directly into the sink flange.

Screw the drain pipe into the sink flange until the putty touches the rim. Hold the sink flange in your dominant hand with the putty facing up. Place the flange lightly over the sink hole from underneath and guide the drain pipe through the opening to the other side. Once you hit the sink flange, turn the pipe clockwise until it catches on the flange’s threading. Turn the pipe until the plumber’s putty barely touches the rim of the pipe. This step is kind of awkward since you need to hold one piece under the sink and one piece over the sink at the same time. You can tell the putty has hit the drain supply pipe when you feel resistance as you twist.

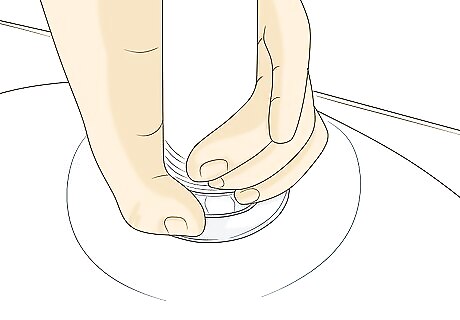

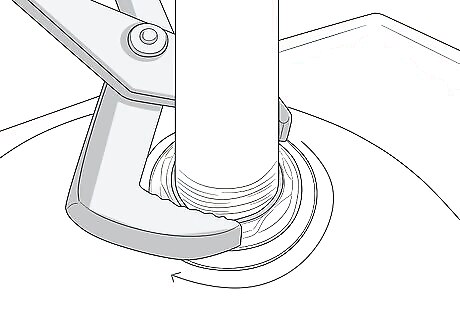

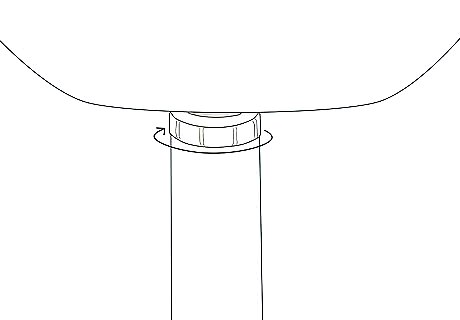

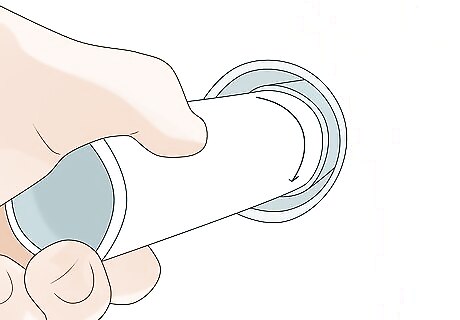

Turn the lock nut clockwise to tighten the rubber gasket against the opening. Once the threading is in place, let go of the sink flange. Hold the drain pipe with your nondominant hand to steady it and turn the metal lock nut clockwise to tighten it. Continue tightening the nut firmly until you can’t turn it any further. You have to turn the lock nut extremely hard to seal the rubber gasket against the base of the sink. This requires a strong grip and a lot of muscle. Turn it as hard as you can to completely seal the pipe. If your lock nut has flat sides, you can use channel locks or a wrench to turn the nut. As you tighten the pipe, the sink flange will tighten into the sink hole at the bottom of the sink.

Placing Your Countertop

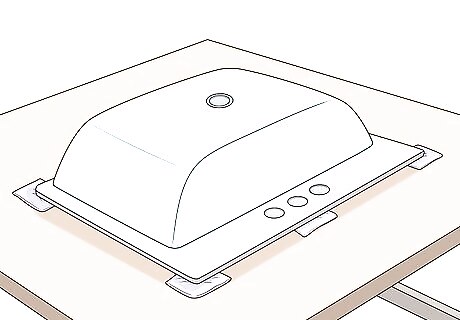

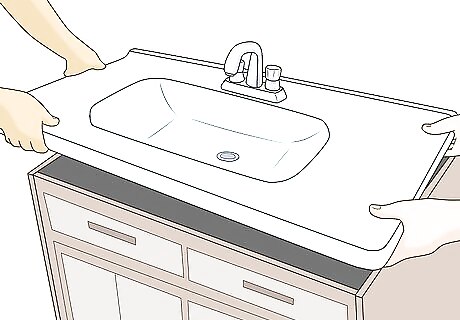

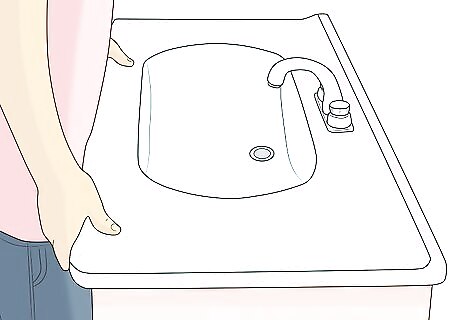

Place your counter on top of the vanity to ensure that it’s level. Grip your counter on two opposite sides and lift it up. Hold it over the vanity cabinets. Slowly lower one side down to brace the sink and set it where you want to install it. If the cabinet and the counter lines up cleanly, remove the counter. If it isn’t level, slide shims between the cabinet and the counter to level it before using wood glue to secure the shims in place. Countertops can be pretty heavy, so enlist a friend to help you lift it if you’re struggling to hold it steady.

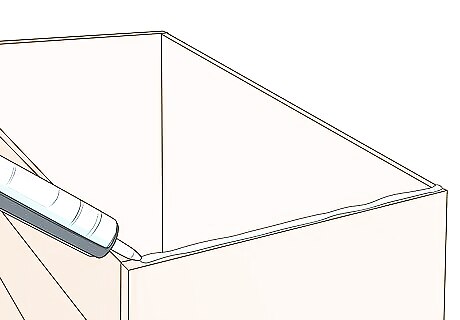

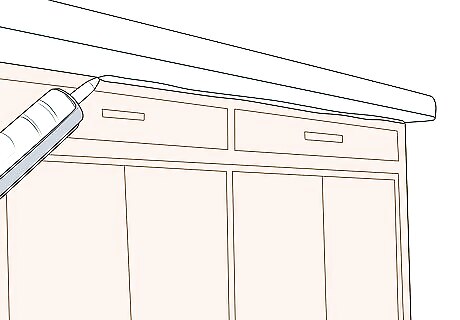

Run silicone caulk along the top of the vanity’s panels. Put the countertop down near your vanity. Slide a tube of silicone caulk into your caulk gun. Cut the front 1 in (2.5 cm) of the tube off. Squeeze a thick line of silicone caulk along the top of the cabinet on every side. More silicone is better than not enough silicone. You can always wipe the excess silicone away after you’re done. Undermount sinks will need to be supported while the silicone dries to avoid cracking.

Lift your countertop up and carefully line it over the vanity. Lift the countertop back up and orient it in the right direction. Carefully hold the countertop over the sink. If you can, enlist a friend to help you with this since the more accurate your initial placement is, the better your seal with the vanity will be.

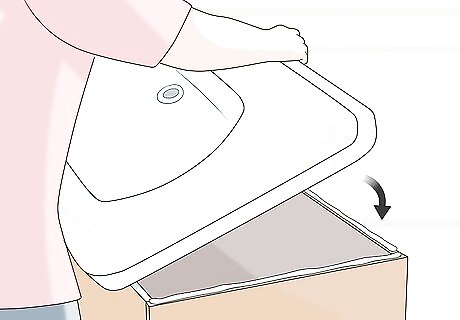

Lower the countertop into place and adjust it as needed. Slowly lower the countertop into place, letting one end down first and then sliding the countertop into place against the wall. Silicone caulk starts to dry quickly, but you have 5-10 minutes to adjust the countertop before it starts setting. Slide the countertop to the proper location where you want it to permanently rest.Tip: If you really want an accurate placement, use a measuring tape or a ruler to calculate the overhang on each side to make sure that the countertop is even.

Seal the joint around the bottom of the countertop with silicone. With the countertop in place, take your caulk gun and bend down under the overhang. Apply silicone caulk to the seams where the overhang meets the vanity. Use your finger to smooth the caulk out and wipe any excess silicone away with a paper towel or your finger. You can apply silicone caulk to the top and side where the counter meets the wall as well if you want to keep water from sliding behind the vanity. If your wall is even and the counter is flush though, this is optional.

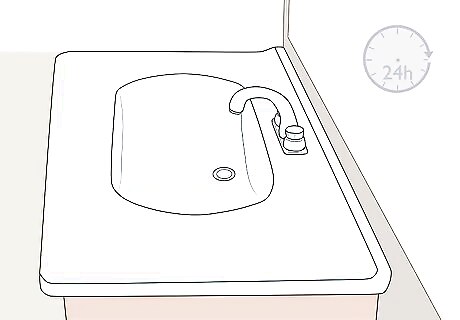

Leave your vanity alone for 24 hours to give the silicone time to dry. Wipe off any excess silicone with caulk and clean up your materials. Leave the room and let the countertop dry for at least 24 hours. Don’t touch or move your countertop or vanity while the silicone is drying out.

Connecting the Plumbing

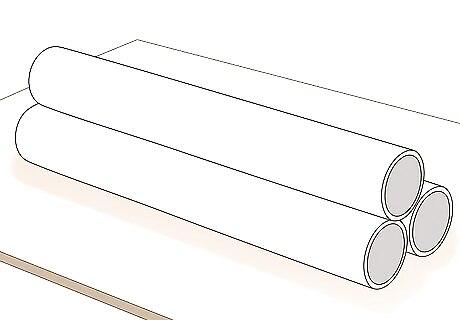

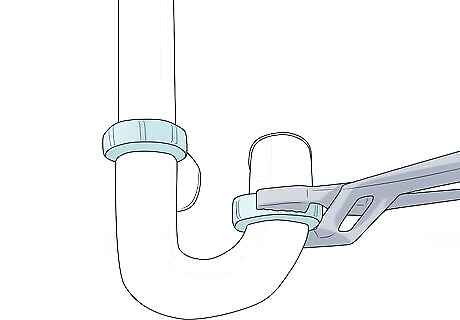

Purchase a PVC or ABS pipe set for your sink. Measure the diameter of the opening at the bottom of the drain pipe to determine the size of the pipes that you need to get for your sink. Unless you have a custom vanity or a unique model, the diameter is probably going to be 1.5 inches (3.8 cm). Buy a PVC or ABS pipe system for your sink. You need one pipe to connect to the drain line, a J-pipe (called a trap) to keep a little water in the pipes and prevent odors from coming up, and a final length of pipe to connect to the drain in the wall.Tip: If the drain pipe doesn’t line up directly over the supply pipe for your water, get a set of pipes with a flexible connection at the end. Avoid metal pipes if you can. They can corrode over time and won’t be as easy to work with as PVC or ABS. Check to see if your drain has threading or not. If it doesn’t, you’ll need to get a sleeve to cover the seam where the two pipes meet. Get pipes with threading instead of smooth connections. Smooth connections require PVC glue and you’ll have to replace the entire system if you ever end up with a leak.

Slide washers or gaskets over the threaded section of each pipe. Open the bottom cabinet doors and set your pipes down. Depending on the set of pipes you got, they either came with washers and gaskets, or they’re only designed to screw into one another. If you have washers and gaskets, slide each gasket with the threading facing up over the opening of each pipe. Place a washer inside the lining of the gasket. A washer is a plastic ring that fits around the pipe. It’s designed to seal the opening around the threading where the gasket meets the pipe.

Screw the straight pipe at the top into your drain pipe. Start with the straight pipe designed to fit into your drain pipe. With the washer on top of the gasket, slide the pipe up to the drain pipe and turn the gasket clockwise. Turn it as hard as you can to adhere the straight pipe to the drain pipe. You may have seen plumbing setups where the straight pipe simply goes around the drain pipe without anything sealing them in place. These systems aren’t ideal, since a blockage in your pipe will cause the water to overflow into your vanity.

Glue or screw the wall connector to the drain line in the wall. With your straight pipe installed, take a look at the pipe in your wall where the water will come out. If it has threading, screw the pipe into the drain line the same way you installed the drain pipe. Many drain lines don’t have threading though. Use PVC glue to cover the end of an unthreaded pipe. Slide the pipe into the drain line with the glued side on the inside. Then, slide a PVC sleeve over the joint and seal it with caulk or PVC glue. A PVC sleeve is basically a small length of PVC that is designed to seal two pipes that don’t have threading.

Install your J-pipe to finish the drain assembly. Screw the trap into the drain pipe using the washer and gasket. Don’t tighten it all the way to ensure that you have a little room to work. Once the J-pipe is partially screwed into the drain pipe, rotate the pipe and use the slack left in the threading to line the drain line with the other end of the J-pipe. This can feel kind of awkward, like you might break your pipe. Unless you’re pulling really hard on the J-pipe it’ll be fine.

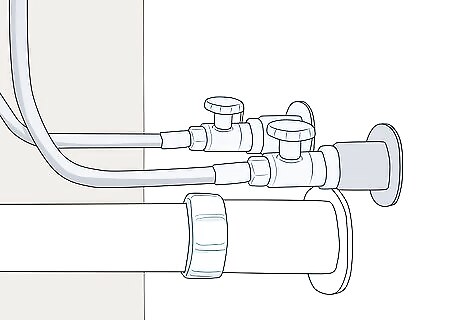

Screw your supply lines into the faucet. Supply lines are flexible tubes that screw into the sink handles and water supply lines. Supply lines are identical, so it doesn’t really matter which line goes into which pipe. Simply screw each line into the pipe until it won’t turn any further. Place your faucet into the openings at the back of the countertop and screw the other ends of the supply lines into the faucet. You can use a wrench to tighten the supply line connections if you really want a firm seal.

Install your faucet with caulk and add the pop up drain. Apply silicone caulk to the bottom of the faucet and press it into the countertop to set it in place. Faucets come preassembled so it’s really easy to install them. If you have a pop up drain, hook the clevis strap to the screw in the lift rod and screw them together. Slide the pivot rod through the clevis strap and place a clip around the opening on the opposite side of the clevis strap to hold them in place. Pop up drains are pretty easy to install. If you have one, the pivot rod will already be attached in the drain pipe, so you only need to slide it through the strap. If there isn’t a pivot rod sticking out of your drain pipe though, you can’t install a pop up drain.

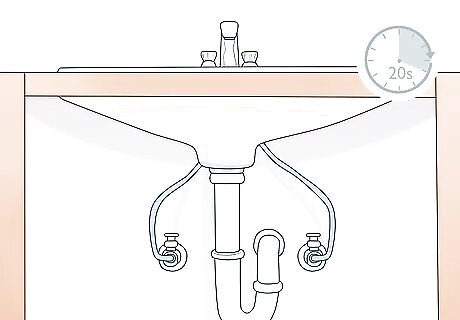

Run the sink for 20-30 seconds to test the pipes and look for leaks. Turn the handles on the supply pipes to open the hot and cold water. Run your water for 20-30 seconds to see if there are any leaks. Run your hands along your pipes to see if there is any water on the pipes. If there is, turn the water off and use putty, glue, silicone, or tape to fix the leaks. Place a towel under the sink to catch any water that may leak.

Comments

0 comment