views

How do you use an adjustable pipe cutter?

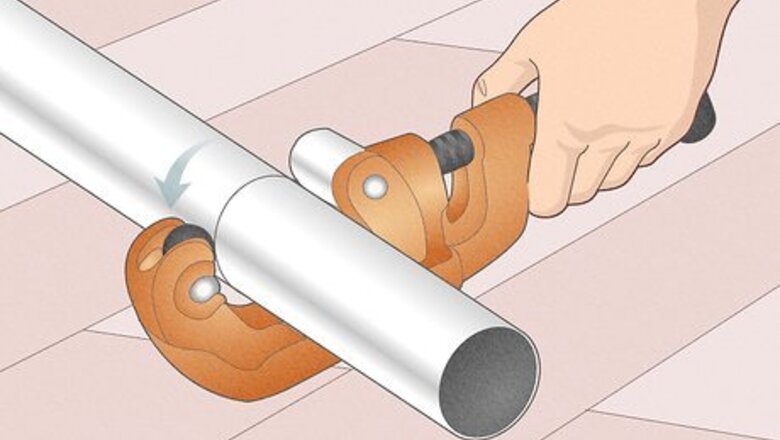

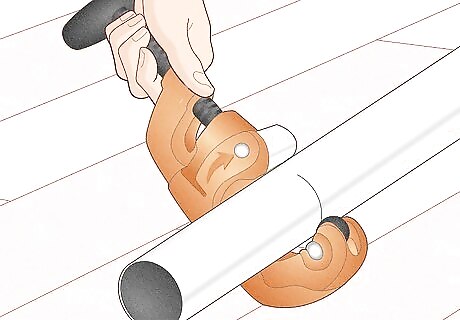

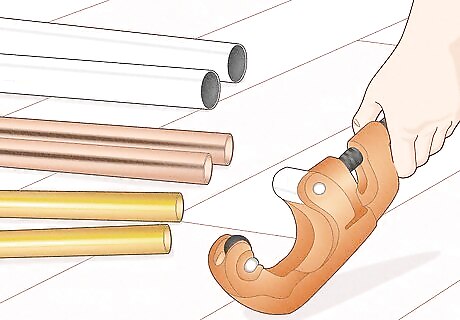

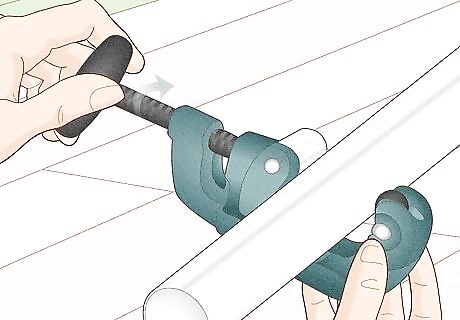

Tighten the jaws around the pipe. Place the rollers of the pipe cutter against the pipe. Turn the tightening screw clockwise until the cutting wheel makes contact with the other side of the pipe. An adjustable pipe cutter looks a bit like a wrench, and is primarily for metal pipes. One side of the jaws has rollers that keep the tool in place on the pipe, while the opposite side has a cutting wheel. A screw on the side of the tool or the end of the handle adjusts the width of the jaws. If the pipe is horizontal, position the pipe cutter so the open side faces upward. Secure loose pipe to a workbench with a vise or clamp before you cut.

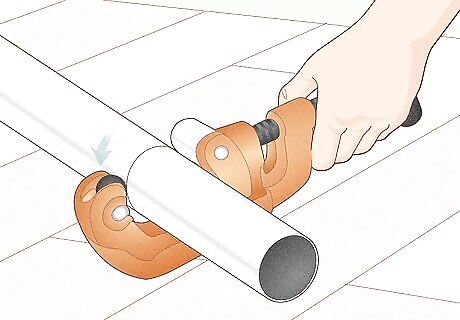

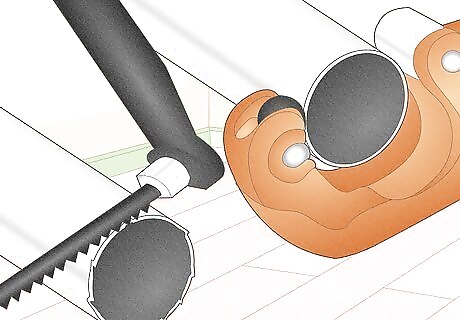

Rotate to make a test groove. Now that you've made contact, tighten the screw just another 1/4 turn. Use the handle of the cutter to rotate the tool 360º around the pipe. This should score a light, perfectly circular groove into the pipe. A spiral groove means the tool is getting off track. Make sure the pipe cutter is designed for the material you are cutting, and try cleaning the cutting wheel and rollers with a wire brush and tool cleaner. If it still won't cut straight, you might need to replace the cutting wheel.

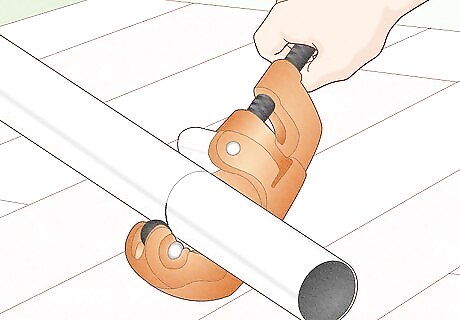

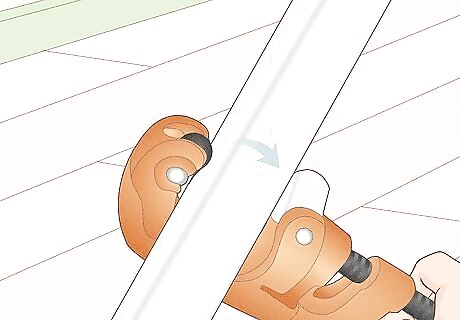

Tighten and rotate repeatedly. Now tighten the screw just enough so you feel tension, and rotate the tool another 360º around the pipe. Repeat this to gradually push the cutting wheel through the pipe. It's much better to tighten too little than too much, since forcing the cutter into the pipe can damage your tool. Try just a 1/4 turn of the screw for every rotation, or even every other rotation. Some fancy pipe cutters have multiple wheels or blades along the jaws to engage the pipe in different positions. These are great for narrow spaces, since they let you rotate the tool back and forth along a smaller arc instead of in full circles.

How do you use a PVC pipe cutter?

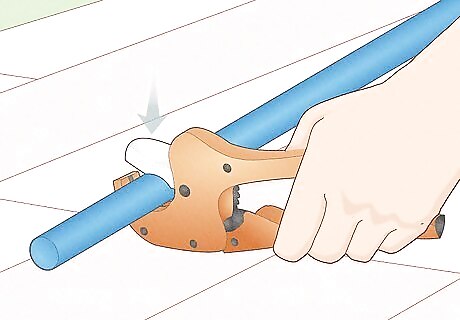

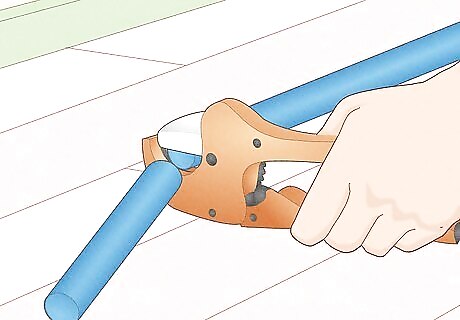

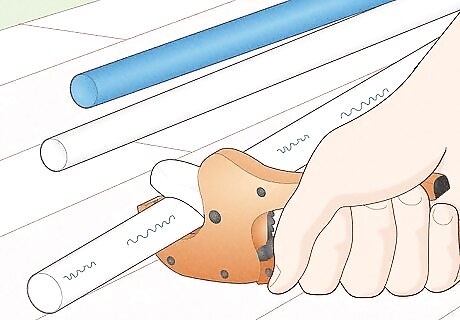

Open the cutter to engage the ratchet, if there is one. A PVC pipe cutter looks like a pair of scissors with a single blade. Open the handles to see if there's more to it than that: The simplest models are just a single blade that clamps down onto the pipe when you squeeze the handles. Line the blade up with your cut mark, squeeze down, and rotate to complete the cut. These typically work only on tubing and the smallest PVC pipes. A ratcheting cutter is larger, and has hinged metal arms between the handles. These engage a ratchet inside the tool which adjusts the angle of the blade to cut gradually into the pipe. These can get pretty-heavy duty, but the largest PVC pipes may require an adjustable cutter. Check your model's product info for the maximum pipe diameter.

Squeeze the handles repeatedly to ratchet the blade through. Line up the blade with your cutting mark. Keep squeezing and releasing the handles to work the blade through the pipe in stages. Secure loose pipe to a workbench with a vise or clamp before cutting, and orient the cutter so the blade is above the horizontal pipe. The largest PVC cutters can be heavy and unwieldy. It helps to place the lower jaw against a table or floor to keep it steady.

How do you use a small pipe cutter (pipe slice)?

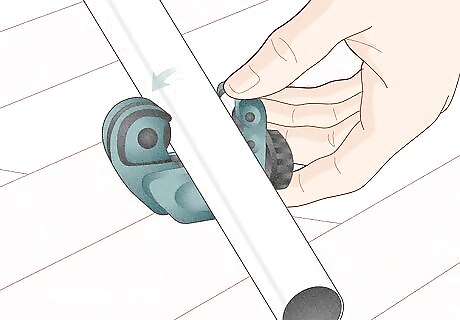

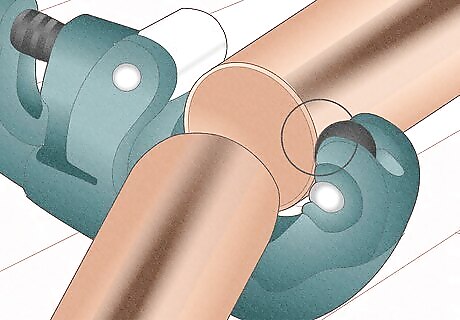

Push the pipe slice onto the pipe. These tiny, circular tools have an opening on one side, and a curved interior that contains rollers for gripping the pipe, and a cutting wheel to slice through it. They are great for narrow spaces, but each one only cuts one diameter of pipe. If the jaws don't fit snugly around your pipe, you'll need to switch to a different tool. Some designs have a little cover over the opening. Unlatch this, then clip it back into place once the cutter is on the pipe.

Keep rotating it around the pipe. Typically, a spring inside the tool pushes the blade into the groove as it gets deeper, until the blade slices through the pipe. This usually takes at least ten full rotations for copper pipe. Check the side of the pipe slice for an arrow telling you which way to rotate. Some pipe slices for cutting plastic tubing are flexible; squeeze these gently as you rotate.

Which way do you turn a pipe cutter?

Follow the arrow on the tool, if there is one. Little, circular pipe slices often have an arrow on the side telling you which way to turn.

Otherwise, rotate so the tip of the tool leads. For larger tools with handles, turn the tool so the top of the tool moves ahead of the handle. Although the tool will cut in either direction, this direction is best for keeping the cutter straight and firm on the pipe.

Can you use a pipe cutter on any material?

Most adjustable cutters work best on soft metals. It's a safe bet that any pipe cutter with an adjustable jaw width will work fine on copper, brass, and aluminum pipes. To cut through steel or iron, you'll need a special model with hardened wheels, and—if you're getting really heavy-duty—an extra-long handle for more leverage. These will also cut through any type of plastic pipe, if you like overkill. This dulls the blade faster, so it's not recommended as your go-to option.

PVC cutter capability varies by product. Almost any PVC cutter can also handle CPVC, PP, PEX, and PE plastic pipes. Look up your specific model to see if it can also cut ABS, PB, or PVDF plastics. Worried about identifying your pipe? Any rigid, light-coloured plastic pipe installed in a home is very likely to be PVC. ABS is black, PVDF is used in industry rather than homes, and PB pipes are flexible. Old plastic pipes can be more brittle, so squeezing them with a scissor- or ratchet-style cutter can cause cracks. An adjustable pipe cutter or a hacksaw are safer options. The risk of cracking is higher in cold temperatures and when the blade is dull.

Each pipe slice is designed for one material and size. Most of these small, circular tools are made to cut a given size of copper pipe. Some tubing cutters, designed either for copper or plastic tubing, use a similar design. These are highly specific tools that are unlikely to even fit onto a pipe of the wrong material.

When should you use a pipe cutter instead of a hacksaw?

Use a pipe cutter when you need a smooth surface. The pipe cutter leaves behind a smooth, mostly burr-free cut. This is great for any pipe used in plumbing, but especially for metal pipes that you plan to solder, or plastic pipes that you plan to solvent-weld. A hacksaw leaves behind a rough edge that takes extra work to deburr and sand before it is ready for bonding. It's still a good idea to clean up the inner surface of the pipe after using a pipe cutter, for instance by running a utility knife around the inside edge.

Use an adjustable pipe cutter when a straight cut is important. Line up the pipe cutter once at the beginning, and you can cut a perfect circle. This is a nice bonus for many projects, but it's especially important if you plan to thread the pipe. To set up a straight cut with an adjustable cutter, fix the pipe cutter snugly onto the pipe, then rotate it around the pipe without tightening it to score a groove. If the groove spirals instead of forming a perfect circle, clean the tool and try again. If you want to join pipes with a pipe joint compound, apply it to the exposed threads of the pipe. Use a plumbing compound that contains Teflon. Teflon expands when it gets wet and seals the leaks.

Comments

0 comment