views

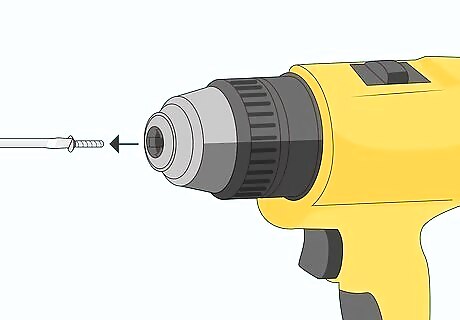

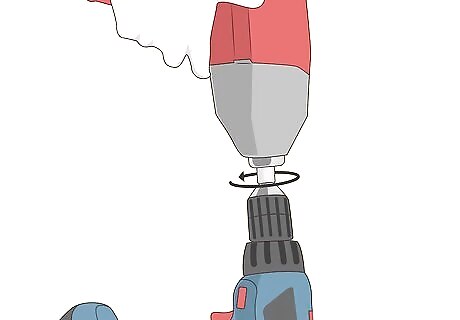

- Remove the screw inside of the drill chuck to unlock it. It’s a reverse screw, so unlock it by twisting clockwise.

- For modern drills that don’t have keys, insert an Allen wrench in the opening and strike it with a hammer or mallet to remove the chuck.

- Keyed drills with no opening on the spindle require chuck wedges. Insert a wedge, tap it with a hammer or mallet, and keep adding force until the chuck pops off.

Allen Wrench for Keyless Chucks (Easiest Method)

Remove the screw in the center of the chuck. Turn the drill off or unplug it. Loosen the jaws of the chuck by twisting them to the left as far as they’ll open. Look inside the chuck where the drill bit would go and look for a screw. Insert a screwdriver of appropriate size and turn clockwise to remove the reverse-threaded screw (it’s righty-loosey in this case). Skip this step if your model does not have a screw. The screw is usually coated with thread-locking fluid, so this may require some force. If the screw won’t loosen up, insert the screwdriver and tap the back with a hammer or mallet to force the head into the grooves. This process applies to the vast majority of modern drills, including Milwaukee, Hitachi, Makita, Black and Decker, and Ryobi models.

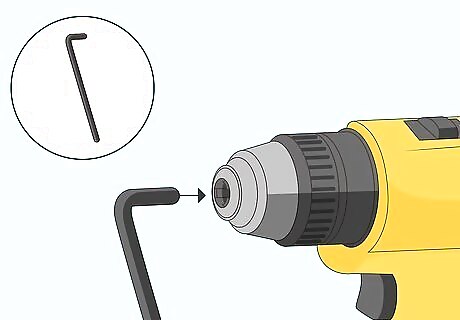

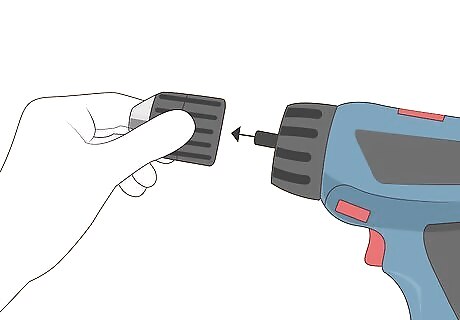

Insert an Allen wrench into the opening of the chuck. Choose the largest Allen wrench you can insert into the opening of the drill. Turn the Allen wrench to tighten the chuck, until it is firmly in place. If you have a table clamp, C-clamp, or vice grip, use it to hold the drill in place. It’s not mandatory, but it’ll make this process a little easier.

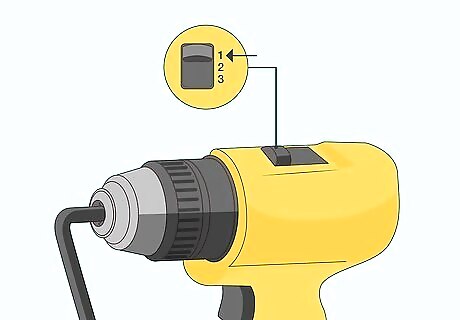

Set the gearbox on the drill to the lowest setting. This will reduce resistance from the gears to a minimum. The gearbox is the little 1-2 or 1-2-3 on top of the drill, so set it to “1.” The 1-10 or -120 on the area just before the chuck are the torque range. They can be set to any number for this—they aren’t providing any resistance.

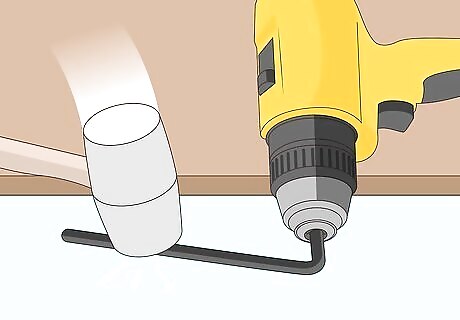

Tap the back of the Allen wrench with a mallet or hammer. Position the drill so the Allen wrench lies horizontal and overhangs your workbench. Give the end of the Allen wrench a sharp downward strike with a wooden or rubber mallet. Most drill chucks have a standard thread, so striking the Allen wrench in a counterclockwise direction should loosen the chuck from the drill. This can bend or crack the drill casing if the strike is too forceful or at an angle. Start with light force and increase it as needed. You’ll probably need to do this more than once. Don’t freak out if you end up having to hit the Allen wrench harder than you’d expect. It can take a lot of force to unlock some chucks. Look, as much as we’d love to promise otherwise, you may end up cracking, breaking, or bending your Allen wrench. We apologize in advance if it happens but it’s unavoidable.

Remove the chuck by hand once it snaps unlocked. Keep hitting the Allen wrench until the chuck “cracks” open (it’s not broken—it just sticks). Once the chuck is loosened from the drill casing, unscrew it by hand.

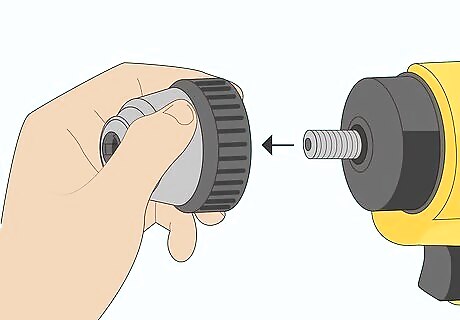

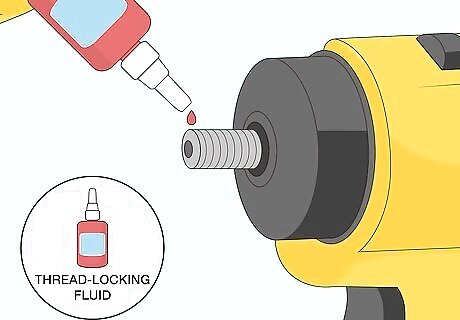

Replace the thread-locking fluid on the screw and install a new chuck. Once you are ready to install a new chuck, dab a bit of thread-locking fluid onto the end of the screw. Roll it on your finger to spread the fluid evenly. If your keyless chuck has no screw, you may need to use thread-locking fluid on the threads of the chuck where it screws onto the drill. Mount the new chuck by threading the base on to the spindle, opening the chuck, and replacing the screw in the middle with a screwdriver.

Hex Socket for Keyless Chucks

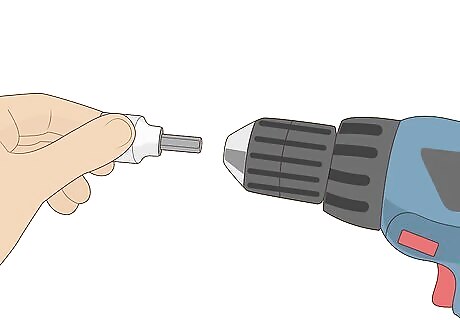

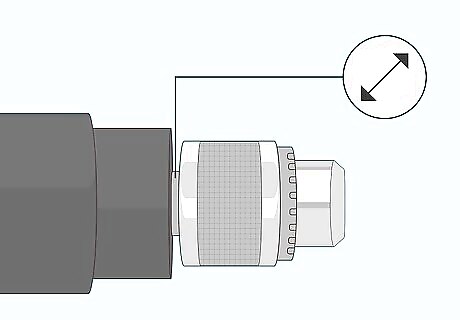

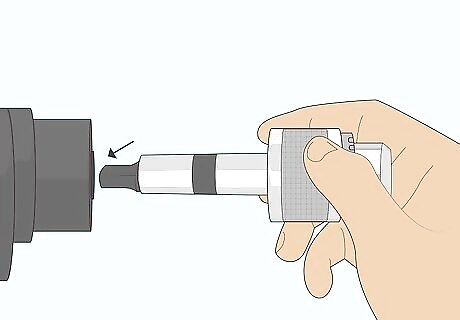

Insert a hex socket into the center of the chuck. If you don’t have an Allen wrench or the chuck won’t come loose no matter how hard you hit it, an impact wrench will provide the force you need to unlock the chuck. Insert a hex socket into the center of your chuck and tighten the chuck to hold it in place. If there is a screw in the center of your chuck, unscrew it first with a clockwise turn. This method may have a higher risk of damaging your chuck or drill. Still, you can’t use a drill with a busted chuck stuck on it, so it’s worth a shot.

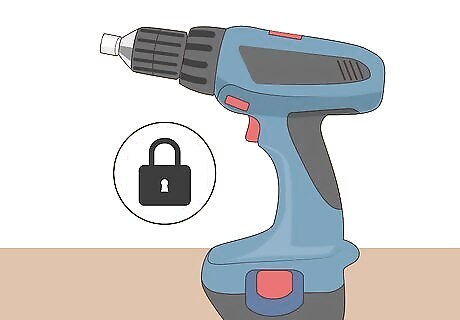

Set the drill direction to the locked position. Set the drill's gearbox to the locked position, neither forward nor reverse. This will provide the gripping power you need to give the impact wrench leverage.

Drive the impact wrench in reverse to unlock the chuck. Place the impact wrench into the hex socket and set it to reverse. Engage the impact wrench in short bursts until the chuck loosens off the drill. Increase the speed/power of the wrench as needed until the chuck comes loose.

Unscrew the chuck by hand and replace it. Once the chuck is unlocked, unscrew it the rest of the way by hand. Put your new chuck on, apply thread-locking fluid, and replace the screw in the middle of the drill and tighten it as needed.

Tapered Drill Chucks with Keys

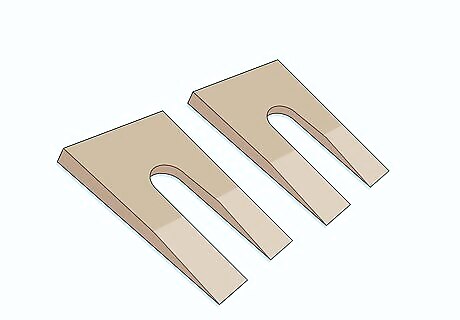

Measure the diameter of the spindle. Keyed drill chucks do not typically thread onto the drill. Instead, the chuck's tapered end inserts onto a matching spindle. Look at the gap between the chuck base and the drill, and you should see this spindle. Measure its diameter. If your chuck does have an opening for the key, you can just use the key to unlock the chuck the same way you’d unlock a drill bit.

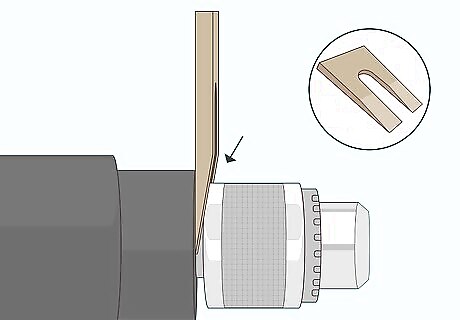

Buy a chuck removal wedge set. These sets contain two cheap, dual-pin wedges. Choose a set with a gap between the two arms slightly larger than the spindle diameter, but as close to it in size as possible.

Insert the wedges between the chuck and the drill. Position the two arms of the wedge around the spindle in this gap. On the other side of the spindle, insert the second wedge. It’s okay if they aren’t perfectly symmetrical with one another since one of them is going to technically be “on top.” You can also just do this with a single wedge. You may need to hold the chuck in place while you work, though.

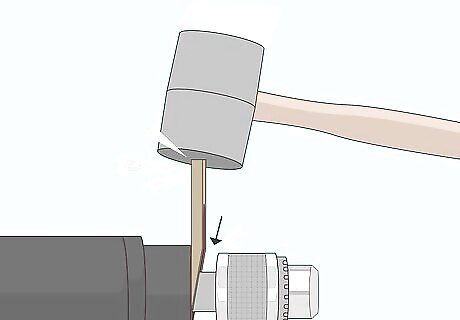

Hammer the wedge in until the chuck pops off. Tap the back of the wedge with a hammer or mallet. Start slowly and keep increasing the amount of force you’re using in small amounts until the chuck begins to move. Then, continue tapping until the chuck falls off.

Insert a new tapered chuck and tighten it. Clean and degrease the tapered portions of the spindle and chuck. Place the chuck on the spindle and retract its jaws completely. Place a thin piece of wood over the chuck nose to protect it, then tap the chuck nose with a mallet until it fits securely onto the spindle.

Comments

0 comment