views

X

Trustworthy Source

Federal Aviation Administration

U.S. government agency responsible for monitoring and setting guidelines for civilian aviation

Go to source

Drilling through Plexiglass is notorious for causing it to crack, but with a round drill bit and low drill speed, this should be a breeze. Just take your time and make sure you have the right equipment. Here, we’ll walk you through the entire process so that you can drill clean, smooth holes without damaging anything.

- Put scrap acrylic or MDF sheets behind the Plexiglass you’re drilling to brace it and minimize cracking.

- Use a spiral drill bit designed specifically for plastic to slowly drill through the Plexiglass at the lowest drill speed.

- Use short bursts of low surges until the hole is drilled. If you smell burning, pour water on the hole as you drill.

Safety & Setup

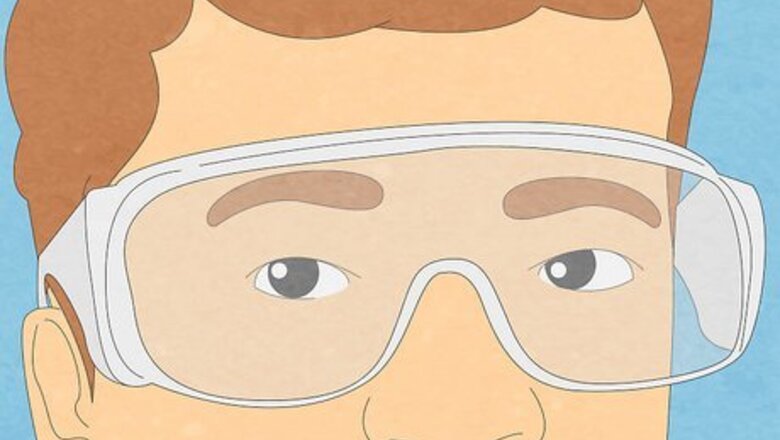

Wear safety goggles. Acrylic can chip quite easily if you aren’t careful, so protect your eyes with protective goggles. If you’re working in an enclosed space with no ventilation, put on a dust mask or respirator, too. Drilling Plexiglass isn’t bad for your lungs, but the aroma of the melting acrylic from the drilling can be kind of unpleasant if you’re sensitive to strong odors.

Acquire some spiral drill bits designed for plastic. Plexiglas, the company that makes Plexiglass, explicitly says spiral bits are ideal when it comes to drilling through their products. These bits have a different geometric structure that digs through acrylic more easily, so they’re less likely to crack the Plexiglass. Attach the bit to whatever drill you’re using based on the size of the hole you’re making. Any drill will work with Plexiglass. You don’t need to use any special tools for this.

Test the drill bit out on scrap acrylic, if possible. Practice with smaller pieces of scrap acrylic before attempting to drill into a large sheet. This will help you get a sense for the ideal speed. The hardest part of this process is getting the speed right, since too slow will cause the bit to skid while too fast will cause cracks.

Preparing and Aligning the Drill Point

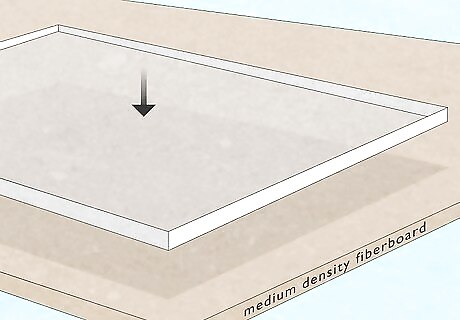

Place your plexiglass sheet on top of a scrap piece. Set the acrylic you’re going to drill through on top of a sheet of damaged Plexiglass or MDF (medium density fiberboard). This will make it less likely that you will chip the back of the board or scratch it when the drill bit goes through. Some DIY enthusiasts have a lot of success putting painter’s tape around the sides of the area they’re drilling through. If there’s a protective film on the Plexiglass, leave it on. It’ll help minimize the odds of a crack.

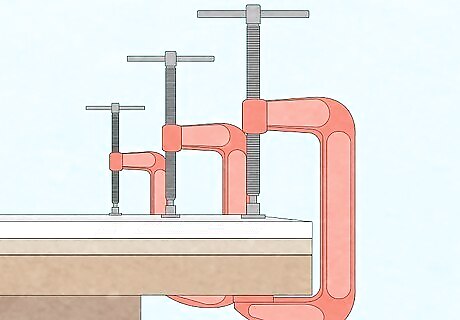

Clamp the Plexiglass and backside to a secure surface. Use as many clamps as is necessary to secure the sheet. For larger sheets, you may need as many as 3-4 clamps. You can secure the sheets between two tables, two sawhorses, or even a single saw table. If you have adjustable C-clamps with custom pressure settings, don’t overdo it. So long as the Plexiglass is stable, it’s fine. If you over-tighten the clamps, you could shatter the sheet.

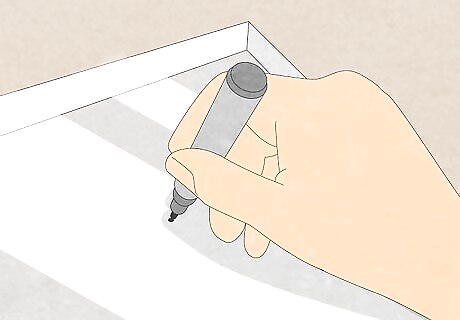

Mark the dot you’re going to drill. Use a dry erase or permanent marker to indicate where you’re going to drill, since it can be kind of tough to stick to a spot on the clear Plexiglass. Also, make sure that the hole you’re drilling isn’t within 3–5 inches (7.6–12.7 cm) of the edge of the sheet. Acrylic is notorious for chipping near the edge when it is punctured. If you do need to drill near the edge, sandwich the acrylic between multiple sheets of MDF or acrylic and only leave the edge exposed. Acrylic and Plexiglass can be kind of hard to drill through since there are no points of reference. Marking the spot will help you keep track of where you’re working.

Driving the Drill Through

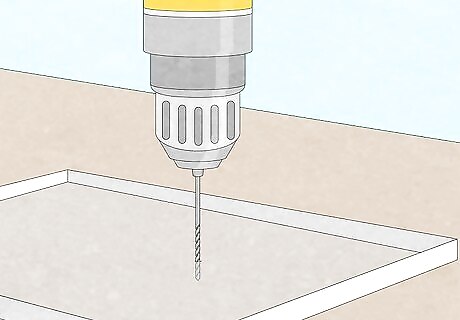

Set your drill to a medium-low speed. Plug your drill in or place a charged battery inside. Then, turn the dial on the front of the drill to one of the lower numbers (if you have options from 20-1, 5 or under are ideal settings. Test the drill to confirm the drill bit is seated perfectly in the chuck. If the drill bit isn’t seated perfectly, unlock the chuck by twisting it counterclockwise and retighten it.

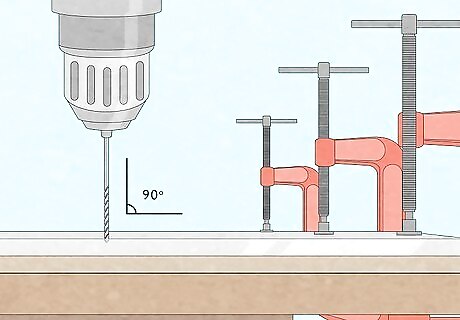

Run the drill slowly into the sheet at 90 degrees. Hold the drill steady over the mark you made at as perfect a 90-degree angle as possible. Maintain a moderate amount of pressure and slowly squeeze the drill. Work slowly in short bursts to ensure you don’t crack the acrylic. If the drill bit skids, just reset and realign your drill bit against the Plexiglass.

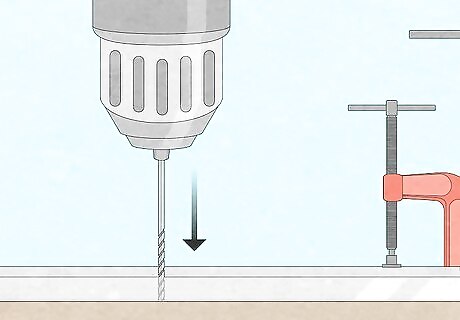

Keep a steady, slow pace. Aim for a calm penetration rate as you continue to drill. Acrylic drill bits will produce plastic shavings, so once they start to surround the drill bit, stop and remove them to get a better view of what you are doing. You can actually tell if you’re drilling at a healthy speed and energy by the shavings. If the shavings come off in thin, coherent sheets like you’re sharpening a pencil, you’re good to go.

Pour water on the cut if you smell or see melting. Plexiglass gets very hot when you drill into it, so it may start to melt if you’re drilling through anything thicker than a fraction of an inch. If you notice the area around the hole you’re drilling melting or you smell burning, stop and pour room-temperature water over the hole. Keep working until you’ve punched out the hole and repeat the process as needed! If your hole is too rough for your liking, deburr it by drilling through the hole again from the opposite side or by smoothing the inside down with sandpaper.

Comments

0 comment